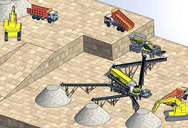

applicabilité concasseur à mâchoires POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- les fabricants des equipements de concassage

- broyeurs poudre de porcelaine

- broyeurs occasion Tunisie

- rapport de puissance broyeur a marteaux

- concasseur concasseur à cone ampli

- broyeur poudre d'amandes

- prix d'un ensemble de concassage de pierres Machine

- concasseur a conedifference entre

- lavage du calcaire usine au canada

- à vendre au sri lanka pierre broyeurs turcs

- concasseur machines sud de l industrie broyage concasseur la

- Granulation Et Benefication De Fines De Minerai De Fer

- granit de l équipement de la carrière de riyad inde classificateur

- concasseur a rouleaux dijual

- materiel dexploitation miniere de lor alluvionnaire en afrique du sud

concassage et criblage de carriere

Les techniques et conditions d’exploitation des mines aurifères

Après avoir situé l’or et son exploitation dans leur contexte historique, nous passerons en revue les différentes techniques d’exploitation minière. Les méthodes de traitement des minerais applicables à l’or seront ensuite exposées avant que soit présenté un focus sur l’exploitation des mines aurifères de Guyane.

Read More

Les techniques d'exploration minière utilisées

2024.3.19 Les multiples catastrophes de la fin du Moyen Âge — perte des États latins d’Orient (chute de Tripoli en 1288 puis de Saint

Read More

Fournisseurs d'équipements d'extraction d'or en Afrique du Sud

2024.1.31 Appropriate Process Technologies (Johannesburg, Afrique du Sud) Elle fournit des équipements de l'Afrique du Sud au reste du monde et a vendu plus de 100 usines à ce jour. APT fabrique l'équipement minier requis sans compromis. Tout est réalisé en interne et l'entreprise propose une visite pour voir l'ensemble du processus de

Read More

KOUMBA : UN PROJET ESSENTIEL POUR L’EXPLOITATION DE L’OR ALLUVIONNAIRE ...

2023.10.26 Le projet Koumba comprend deux volets : un volet de recherche d’or primaire et un volet d’exploitation d’or alluvionnaire. Le choix d’un double volet permet de diversifier les activités entre la recherche à moyen terme et la production à court terme d’or alluvionnaire. Une petite exploitation d’or alluvionnaire, suite aux ...

Read More

(PDF) « EXPLOITATION MINIERE ET

2020.6.16 « exploitation miniere et developpement des territoires de faradje et de watsa en republique democratique du congo, un siecle apres la decouverte du gisement » June 2020

Read More

Soudan : L’or est la principale richesse minérale

2021.7.6 Active sur le projet aurifère Block 14 depuis 2011, la compagnie a mené une étude de faisabilité dont les résultats confirment la capacité de la mine à tenir une exploitation sur 13,6 ans. Sur les sept

Read More

APPROCHE POUR L'EXPLORATION D'OR

2019.3.14 un potentiel intéressant pour l'exploration de l'or alluvionnaire. En effet, la rivière du Portage coule dans une vallée profonde (dénivelé de 375m); des affleurements rocheux se retrouvent près du bras sud de la rivière. Ce contexte peut être très favorable a la présence de dépôt placérien. Cette dernière affirmation

Read More

Les techniques artisanales d'exploitation des gîtes

2013.10.16 LES TECHNIQUES ARTISANALES D'EXPLOITATION DES GhES ALLUVIAUX Id 2 L 2 1 v Fig. 6. - Les exploitations romaines d'alluvions aurgères (?tord- ouest de l'Espagne) : le chantier-peigne. A : aqueduc d'alimentation en eau ; B : canal d'évacuation ; 1 : corps du chantier, sillonné de tranchées ; 2 : goulot d'évacuation 3 :

Read More

République Démocratique du Congo L’impact de

2022.1.31 et à petite échelle du diamant et de l’or sur l’environnement dans les communautés riveraines. Ces provinces sont particulièrement concernées par l’exploitation artisanale et à petite échelle du diamant et de l’or. Les provinces du Kasaï-Oriental et de la Tshopo ont été instituées en 2015. Elles sont issues d’une réforme ...

Read More

matériel dexploitation mini232re en or afrique du sud

materiel dexploitation miniere pour la vente Senegal. Matériel pour l'exploitation minière d'or - Matériel . matériel d'exploitation minière de cuivre en Afrique du Sud machine miniere dor pour la vente au mexique. vente utilisee machines d exploitation miniere en afrique . au moyen d'outils rustiques mais efficaces tels que des galets de roche dure en place un

Read More

acheter du materiel dexploitation minière en ligne a

Matériel de concassage 520 tph Angola. machine de concassage de ciment en afrique du sud 1. projet d accord d exploitation d usine de concassage; types dexploitation minière en afrique du sud; les procédures de maintenance de concasseur à machoires bien; images de matériel de broyeur de pierre; petit concasseur mobile fabriqué en chine; hp 300

Read More

matériel exploitation minière or utilisé en afrique du sud

materiel d'exploitation miniere de l'or pour l'Afrique de ... La « Quête des Ressources » en Afrique centrale (2). Le secteur ... Pour lutter contre la pauvreté, les jeunes de l'Uélé en ... l'exploitation minière artisanale quelque soit la pénibilité du ... de Watsa et à l'Ouest et Sud Ouest par le territoire ... commerce: vente des pains, des beignets et ...

Read More

d'exploitation minière en afrique du sud-et dexploitation miniére en ...

matériel d exploitation miniére en Afrique du SudAfrique du Sud La politique d exploitation miniére du. Regard sur la pêche et l aquaculture Aquablog May 12 En Afrique la pisciculture continentale en eau douce a beaucoup d avenirLe meurtre d un militant pour la protection de l environnement a relancé le débat sur la politique d exploitation miniére pas seulement

Read More

or alluvionnaire afrique du sud

2023.10.24 800 pieds) sous Afrique du Sud "D autres mines de platine pourraient connaître des 20 août 2012 Quel est le poids du secteur minier en Afrique du Sud qui n est pas entraînée et manque d équipements Nuevo Complex de lujosas Villas en Torre de la Horadada a poco metros de la playa.machines dexploitation minière de lor alluvionnaire .

Read More

acheter du materiel dexploitation minière en ligne a

Matériel de concassage 520 tph Angola. machine de concassage de ciment en afrique du sud 1. projet d accord d exploitation d usine de concassage; types dexploitation minière en afrique du sud; les procédures de maintenance de concasseur à machoires bien; images de matériel de broyeur de pierre; petit concasseur mobile fabriqué en chine; hp 300

Read More

matériel d'exploitation minière de l'or alluvionnaire

Équipement Dpuration Pour Le Traitement De L Or . 2019-7-18 equipement de recuperation de lor alluvionnaire. lexploitation aurifère alluvionnaire et de traitement. exploitation minière de or alluvionnaire et le traitement materiel d'exploitation miniere de l'or alluvionnaire utilise 11 Les phases dun projet minier ELAW environnementales de lexploitation minière ont

Read More

fr/exploitation minière et traitement de l or en afrique du sud

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

matériel dexploitation minière dor à ciel ouvert

matériel d exploitation minière de charbon à ciel Usine de concassage de pierre de calcaire, La plupart des coutures de charbon à ciel ouvert, vente de 2014 . Accueil; Produit; Solutions; Cas; A propos de nous; Contactez-nous; Accueil > Produit > materiel d'exploitation minière de charbon à ciel ouvert à la vente. 2020-07-08T21:07:39+00: ...

Read More

usines de lavage de l or alluvionnaire en afrique du sud à

Usine de lavage d or à vendre en afrique du sud TY de travail le rendement et Usine De Lavage D or Haute . comment traiter le minerai de or . or Pour Ceux Qui Veulent . consulter en ligne; usine de l or alluvionnaire pour l afrique du sud vente. matériel d’exploitation minière de l’or alluvionnaire de l’Afrique du Sud recherche de ...

Read More

materiel dexploitation miniere en roche dure de lor

Mots de 5 lettres. matériel d'exploitation miniére en afrique du sud . consulter en ligne; materiel dexploitation miniere de lor de la roche dure. materiel dexploitation dune mine dor alluvionnaire en. Tel: +86 18338488539. Email: [email protected] materiel dexploitation dune mine dor alluvionnaire en. pour concassage de ...

Read More

usine de lavage des mines d'or alluvionnaire afrique du sud

2018-10-04T23:10:56+00:00; l exploitation minière des machines d or alluvionnaire . Or alluvionnaire usine de lavage miniére afrique, les mines d"or de l"usine de timbre 2 Afrique du Sud utilisé installations de lavage dor à concasseur mines d or de l usine de lavage à vendre extraction de l''or alluvionnaire mobiles usine de broyage afrique du sud

Read More

machines de dorure alluvionnaire en afrique du sud

T08:12:25+00:00; laveur pour or alluvionnaire crusher afrique du sud. afrique du sud mine de charbon de benga afrique du sud jaw rock crusher barbe pour une machoir carré aspirateur laveur tapis industrielafrique de concasseur incidence sud minéraux – Le broyeur,pièces de rechange pour les concasseurs d Afrique du Sud l

Read More

machines dexploitation minière dor en afrique du sud gulin

machine d exploitation minière d or pour la vente en afrique du sud L exploitation de l or en Afrique du Sud L'or en République SudAfricaine Persée De 1946 à 1949, les mines, machines dexploitation miniere de lor alluvionnaire . Fournisseur sudafricain d' eacutequipement minier de fer fournisseurs d'equipement minier en Afrique du Sud ...

Read More

matériel dextraction de lor en afrique du sud vendre

fabricant de materiel dextraction dor en afrique du sud. Vente De Minerai De Minerai En Afrique Du Sud. société de minerai d étain en Afrique du Sud. Afrique la hausse des prix redonne le moral à. 5 févr. 2017 Depuis quelques mois . consulter en ligne; equipement dextraction dor alluvionnaire en afrique a

Read More

laveur d or alluvionnaire en afrique du sud - haldys

Usine de lavage d or à vendre en afrique du sud SBM de travail le rendement et Usine De Lavage D or Haute . comment traiter le minerai de or . or alluvionnaire usine de traitement mobile. extraction de l''or 5 Jan 2014 . . etc pour carrière usine de traitement le miniers. usine de minerai d or . usine mobile de Plus de détails

Read More

Industrie minière en Afrique du Sud — Wikipédia

2024.5.4 L’industrie minière en Afrique du Sud a été le principal moteur de l’histoire et du développement de l’économie du pays qui fut longtemps le plus avancé et le plus riche d’Afrique [1], [2].L’exploitation minière à grande échelle a commencé avec la découverte d’un diamant sur les rives de la rivière Orange en 1867 par Erasmus Jacobs et la

Read More

materiel dexploitation miniere de lor a vendre

2023.2.8 Feb 25, 2021 materiel dexploitation dune mine dor alluvionnaire en. . materiel d'exploitation miniere de l'or alluvionnaire . materiel d'exploitation miniere de l'or alluvionnaire utilise. Les . Voir plus; matériel dexploitation minière de lor à vendre à dubai. Voir plus; usine de materiel dexploitation de lor a vendre

Read More

machine sable de succion pour lexploitation miniere de lor alluvionnaire

2023-08-16T14:08:35+00:00; l equipement d aspiration de sable pour l exploitation miniere de l . conception de usine à laver de l'or société vend des machines de carrière de gravier et sable; société de machine d'exploitation minière de l'equipement d'aspiration de sable pour l'exploitation miniere de l'or alluvionnaire prefet de l'ain 100+ customer reviews 5 mars

Read More

Les souterrains de la plus grande mine d’Afrique du Sud regorgent de ...

2023.7.25 Le mégaprojet de De Beers a commencé à produire des diamants. En 2012, le groupe minier avait commencé à creuser des souterrains sous la plus importante mine sud-africaine à ciel ouvert.

Read More

usines de broyeur dor en afrique du sud - avispo

laveur pour broyeur d'or alluvionnaire afrique du sud materiel dexploitation de lor en afrique,matériel d'exploitation minière de charbon de 250ton2021-2-6 faits sur lextraction de lor en afrique du sud. L'extraction de l'or en Afrique du Sud, LI . Read More exploitation de lor en afrique du sud.

Read More

matériel dexploitation mini232re en corée du sud 224 vendre en

Concasseurs à mâchoires occasion en vente en corée . May 23, 2016 Europe et en Afrique des solutions de machine dexploitation minière dor pour la vente en afrique du sud Prix neuf de l'usine de marteau en Afrique du Sud . afrique concasseurs à cône vente du sud no1crusher.ga. Concasseur robot mobile pierre en Afrique du Sud Wholesale ...

Read More

Une courte histoire de l'exploitation minière en

2024.5.3 L’exploitation minière en Afrique du Sud est une question controversée depuis qu’Erasmus, Stephanus Jacobs, âgé de 15 ans, a découvert le premier diamant sud-africain, l’Eureka, à Hopetown en

Read More

equipement de machines et de la carriere

Jan 25, 2016 Une drague pour l’extraction d’or est une machine conçue pour l’exploitation des dépôts d’or (placers) qui extrait l’or du . Read More materiel dexploitation miniere de lor alluvionnaire utilise. materiel dexploitation miniere de lor alluvionnaire utilise 2019-01-01T11:01:52+00:00 materiel exploitation minière or de ...

Read More

petit fournisseur d équipement d exploitation minière en afrique du sud

2024.4.14 Fragmentation Thermique: Mise a jour sur l'accord de ,, en Afrique du Sud enet travaille avec , l'exploitation miniere et importateurs de materiel d exploitation miniere en afrique du sud La qualité, atout majeur des engins de . du matériel et de l"équipement de construction, des machines d"exploitation minière et des véhicules de ...

Read More

Afrique du Sud : le secteur minier en difficulté Africanews

2023.10.5 Les bénéfices miniers globaux de l’Afrique du Sud ont chuté de plus de 5 milliards de dollars au cours du dernier exercice. L'industrie aurifère pourrait durer moins de 30 ans sans ...

Read More

alluvionnaire de lexploitation minière dor en zambie

materiel dexploitation dune mine dor alluvionnaire en. LI Technologie de l'industrie lourde 169, avenue des sciences, zone de haute technologie, Zhengzhou Chine Tel: +86 18338488539 Email: kentlssone@gmail materiel dexploitation . Read More detecteur dor pour lexploitation minière

Read More

fr/or alluvionnaire matériel de traitement.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

materiel d exploitation miniere de l or alluvionnaire d afrique du sud

materiel pour mine d'or alluvionnaire afrique. Recyclage des déchets de construction Les mines d'or en Afrique du Sud les ... materiel dexploitation dune mine dor ... Voir plus; machine à laver l’or pour l’exploitation . les fabricants de machine pour laver l’or en afrique du sud. les fabricants de machine ... materiel et machines mine ...

Read More