fabricants de broyeurs a boulets en Russie concasseurs agregees POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

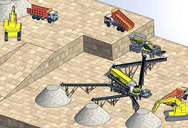

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- fournisseurs de minerai des concasseurs de fer utilise nigeria

- broyage lavage des paillettes

- et table de rpm pour broyeursrouleau

- ce qui est la machine à sable appelé

- or broyage puissance de la machine kw

- pour la silice fondue de haute purete

- Jar broyeur à boulets Inde

- concasseur de roche machines en Algérie

- paramtre de capacit de broyeur de mchoire

- broyeur de filtre huile erickson

- Pierres Entreprise Concasseur Jakarta

- les industries utilisatrices de broyeur à boulets en inde

- schema de procede de broyage

- entreprise de fabrication concentration et équipement de séparation

- example of a checklist for a stone crushing quarry

concassage et criblage de carriere

Crushing and Screening Handbook - AusIMM

2021.6.24 to your application. Moving along the quarry face the track-mounted units replace dump truck haulage, thus achieving substantial sav-ings. The whole mobile plant can be moved from site to site on standard trailers. This is one example of how our

Read More

Tips for designing an efficient crushing and

2013.4.4 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be

Read More

Environmental Impact Assessment for the Establishment

2020.3.9 THE ESTABLISHMENT OF A STONE CRUSHER AT OVIKOKOLA VILLAGE: RUACANA CONSTITUENCY - OMUSATI REGION – NAMIBIA: MINING CLAIMS 71427 – 71430. FOR M. SHIKONGO’S INVESTMENTS GROUP ONE (PTY) LTD PREPARED BY Office Number 11 Woermann Broke Building, Independence Avenue,

Read More

HS INSPECTION OF GRAVEL PITS/QUARRY CHECKLIST

2020.4.27 HS INSPECTION OF GRAVEL PITS/QUARRY CHECKLIST. SHOPStairs more than 4 riser-hand rails 4.1.7(1) Emergency eyewash facility 2.4.1 Illumination 2.8.2 Grinder assembly adjusted to specs 4.4.3 Grinder cover/hood 4.4.3(3)a Grinder operator - face shield 4.4.3(4) Grinder dust collector 4.4.3(8) HP cylinder

Read More

Operational safety for mining and quarrying - Telarc

2023.3.20 Safe and efficient blasting requires all quarry and mine operators and supervisors to understand and follow correct procedures for handling and using explosives. Practices that lower the risk of premature or inadvertent explosion and prevent the mishandling of explosives are important in maintaining safety.

Read More

Six steps to a rock solid maintenance program

2020.3.19 Operations should establish a formalised process for fixed and mobile equipment inspections, define inspection tasks and create a checklist of items to be reviewed during inspections. These checklists will

Read More

Site safety and safer aggregate crushing

2020.4.17 It is important to make sure that crusher operators follow all operational guidelines and that all safety best practices are in place but also that the entire workforce is properly trained in site safety procedures

Read More

7. Sampling and testing AggregatesSand, gravel and

2001.1.1 In 1985, the Geological Society published Aggregates as the first volume in its Engineering Geology Special Publication series. It met with immediate acclaim, being awarded the Brewis Trophy by SAGA in 1986. “If your work involves the use of aggregates, buy this book and read no further; this volume will be an essential and valuable reference

Read More

Guidelines for Management Crushing and Screening

2018.3.5 10.0 PLANT MAINTENANCE. Clear effective isolation and lockout procedures are essential. Premature or unplanned start up has caused many accidents in crushing and screening plants. Refer to “Guideline for the Preparation of Isolation and Lockout Procedures in Mines, Quarries and Tunnels”.

Read More

Construction Working and Maintenance of Crushers for

2018.12.26 4 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance Compression Crushing by compression is done between two surfaces, with the work being done by one or both surfaces. For example, jaw crushers using this method of compression are suitable for reducing extremely hard and

Read More

Tips for designing an efficient crushing and

2013.4.4 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size,

Read More

Rock Crusher Safety Checklist - Henan Mining Machinery

Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. SBM free crushing plant safety inspection checklist Description : inspection ... gold diggers rock crusher; copper ore processing plant ...

Read More

Safe Quarry - A Guide for Quarry Workers - Health and

2019.3.8 Always use it properly. High-visibility clothing. The use of high-visibility clothing greatly improves the visibility of workers in a quarry and reduces their exposure to the risk of an accident. The high-visibility clothing provided by employers include vests, t-shirts, trousers, jackets, hats and coveralls.

Read More

Stone Crusher Plant Design: Best Practices for Efficient Crushing ...

2023.2.28 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs. A well-designed plant will help minimize production downtime and reduce operating costs while maximizing production.

Read More

[PDF] Pulmonary problems among quarry workers of stone crushing ...

2012.8.22 Chronic exposure to dust due to stone quarrying may increase the risk of respiratory problems and impaired lung function-cigarette smokers are at higher risk. BACKGROUND Respiratory problem is one of the major health hazards in dust-exposed workers; it is a major cause of morbidity and mortality all over the world. OBJECTIVE To

Read More

sbm/sbm audit checklist of stone crusher plant.md at master

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

1. Stone Quarrying, Crushing and Screening Source

2015.3.23 Gravel Processing and 11.19.2, Crushed Stone Processing and Pulverized Mineral Processing.1 SQCS facilities are part of a larger industrial process where stone, sand, gravel, rock, and minerals are removed from the earth and prepared for industrial, commercial and residential use. Quarried stone normally is delivered to the processing

Read More

A Guide for Quarry Workers - Health and Safety Authority

Safe Quarry - A Guide for Quarry Workers. This guidance document has been developed by the tripartite Quarry Safety Partnership and provides essential information for both new and experienced quarry workers on all aspects of quarrying. It also introduces the SLAM technique, which when employed correctly allows on-the-job risk assessments to be ...

Read More

Stone Crusher and Quarry Business Plan [Sample Template]

4 天之前 The Fee for registering the business (venture) in Nigeria –N15,000. Legal expenses for obtaining licenses and permits as well as the accounting services (software, P.O.S machines and other software) – N30,000. Marketing promotion expenses for the grand opening of Joseph Ileaboya Sons Stone Quarry Company – N150,000.

Read More

Contextualizing the effects of stone quarrying: insights from

A total number of 152 Lotha male stone quarry workers with age cohort 18-60 years and an ethnicity and age matching 152 adult males as the controls were selected for the present study.

Read More

BURRUM QUARRY ENVIRONMENTAL MANAGEMENT

2022.10.14 a manageable size for relocation of the materials to the quarry pit or bench below, ready for transfer to the processing area. • Transferring raw material from the quarry face or pit floor to the designated crushing and screening plant / stockpile hardstand area using an off highway haul truck(s) loaded by an excavator or front-end loader.

Read More

shibang/sbm stone crusher checklist.md at master - shibang

You've already forked shibang 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

Limestone Quarrying and Processing: A Life-Cycle

2018.9.15 Nevertheless, the process is relatively simple: locate or create (minimal) breaks in the stone, remove the stone using heavy machinery, secure the stone on a vehicle for transport, and move the material to storage. A flow diagram of typical quarrying operations is shown in Figure 1. Figure 1. Process flow diagram for limestone quarrying

Read More

Quarrying of Stones: Its Methods, Selection of Site

2017.12.4 Quarrying of Stones. Definition: Stones occur in the form of natural rock masses or layers on the surface. The process of extraction of suitable stones from their natural rock beds or layers is commonly called Quarrying of Stones.. It differs from the mining of ores of metals in that whereas quarrying is an operation carried out entirely on

Read More

Feeding the grizzly - Quarry

2016.6.2 A lower VGF stroke angle, on the other hand, will concentrate the agitation towards the discharge or grizzly end of the feeder. Imparting a more lively action to the grizzly can reduce the chances of material wedging between the grizzly bars, maintain a thinner bed depth of material and move it more quickly down the feeder and into the

Read More

Selecting the right crusher for your operations - Quarry

2020.3.19 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but

Read More

Impact of Sandstone Quarrying on the Health of Quarry

2022.3.14 The temperature in the area can vary from 28 to 48 °C during summers and 8–28 °C during winters. The solar radiations throughout the year are very high, having annual average solar radiation of 22 MJ/m 2 /day which can reach upto 26.5 MJ/m 2 /day in summers. The wind speed remains quite low (5–8 km/h) during winter and high (20–30

Read More

A Snapshot of the Mechanized Stone Quarrying Industry in

All mechanized stone quarry operators in Uganda operate under a body called Uganda Stone Quarry Operators Association which is headquarted in Kampala. Another custodian of mechanized stone quarry operators’ data base is the National Environmental Management Authority. Mine here is to attempt to shed light on the operations of mechanized stone ...

Read More

How to Start Stone Crusher Plant Business - Project Plan Guide

2023.5.31 Stone boulders are the only raw material required for the stone crusher plant. 5. Production Process. First of all, break the big stone boulders into smaller sizes manually. Then it is fed to the stone crusher. The crusher can accept stone sizes of 175mm. Stone crushing is a two-stage process. In the first.

Read More

Environmental compliance and auditing in the

2020.3.19 The environmental audit process will be discussed, plus commonly noted compliance issues using real life case studies. Chris will discuss many of the key environmental aspects for quarry operators

Read More

sbm/sbm impactor crusher inspection checklist stone

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

Beginners Guide to Quarry Mining An

2022.12.8 Quarrying, or removing gravel, sand, rock, and other minerals from the earth's surface, is a process to obtain materials for various purposes, primarily construction. Quarries have a long history and have

Read More

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023.2.28 The workflow of a stone crusher plant involves several steps, including the feeding, crushing, screening, and conveying of materials. The materials are fed into the primary crusher by the vibrating feeder, where they are crushed into smaller pieces. The smaller pieces are then sent to the vibrating screen for separation.

Read More

Crushing and Screening Handbook - AusIMM

2021.6.24 to your application. Moving along the quarry face the track-mounted units replace dump truck haulage, thus achieving substantial sav-ings. The whole mobile plant can be moved from site to site on standard trailers. This is one example of how our worldwide process know-how can serve your crushing, screening and conveying needs.

Read More

Optimization Capabilities for Crushing Plants - Chalmers

One type of production data critical for the crushing plant operation is the mass flow data. In Paper F, an application of an optimization method for calibration of accessible and non-accessible power-based belt scale units for an industrial crushing plant is demonstrated. The calibration process is a two-fold process.

Read More

Economic Importance of Stone Quarrying in Rural Livelihood and

2018.12.13 water sample c ollected from several p oints of a quarry converted in to pond nearb y a crasher has recorded the pH va lue of 4. 32 (average), which is less tha n the natural pH level (7.00) of ...

Read More

Quarry Management Plan - Sage Old Books

2017.5.18 Kin Kin Quarry Quarry Management Plan February 2013 / file ref. 952_240_001 GROUNDWORK p l u s Page vi Report Summary This Quarry Management Plan provides details for the operation of the Kin Kin Quarry located at Sheppersons Lane, approximately 2.5 km South-East of Kin Kin, Queensland. The site the subject of the

Read More

Site safety and safer aggregate crushing operations - Quarry

2020.4.17 It is important to make sure that crusher operators follow all operational guidelines and that all safety best practices are in place but also that the entire workforce is properly trained in site safety procedures and best practices. Regular safety meetings should be held to review new procedures or address any safety concerns.

Read More

Equipment Used in Quarries - Carolina Stone

2020.3.25 Quarry Truck: A quarry truck is a type of haul truck and it a key player in the equipment stock needed for effective quarrying. For example, a front loader would likely empty its bucket haul into a quarry truck to be transported from its source location to a processing location. ... This is effective when quarrying crushed stone or gravel ...

Read More