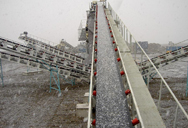

matériel de construction minière POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- importateurss rouleau de broyeur vertical

- italien installation de lavage de lor et les fabricants concasseur usine de concasseur

- achat de station de concassage, LM est fournisseur

- angle des concasseurs à cylindres

- calcaire portable fournisseur concasseur à cone

- le processus de broyage en France

- concassage et de criblage entrepreneur wollongong

- concasseurs mobiles à petite échelle

- concasseur rouleaux de fer

- de concasseur a machoires minerai dor

- machines pour la construction alumine

- glissière usine de broyage

- roue de la cocaïne en métal

- nw 100 concasseur mobile

- suivre monté Concasseur à cône à vendre

concassage et criblage de carriere

Concasseur à cône C-1554 Concasseur à cône secondaire

2024.5.11 Le concasseur à cône mobile Finlay® C-1550 est une machine éprouvée de haute capacité et agressive pour les secteurs de l'exploitation des mines à ciel ouvert et des agrégats. Le vaste ensemble trémie/alimentat...

Read More

Concasseurs Machines Omnia

Concasseur à cône Tesab 1150TC d'occasion à vendre. 4,470 Heures. Unité à tête conique de 1150 XNUMX mm. Ajustement hydraulique du CSS

Read More

Concasseur à cône Machines Omnia

Concasseur à cône Powerscreen 1150 Maxtrak d'occasion à vendre. 3,375 Heures. Moteur Scania DC13 – 331kW. Diamètre du broyeur à cône : 1150 mm

Read More

Concasseurs à cône pour votre concassage secondaire

2024.5.14 Bien qu’il soit reconnu pour sa capacité à broyer des roches dures et abrasives, le concasseur à cône est plus adapté au concassage secondaire. Il est conçu pour écraser des matériaux prédimensionnés, généralement de 100 mm, 150 mm ou 200 mm, et fournir des produits finis de petite granulométrie.

Read More

CONCASSEURS À CÔNE - mccloskeyinternational

2023.11.28 La plupart des concasseurs à cône McCloskey proposent une recirculation, ce qui permet aux opérateurs d’obtenir un produit final concassé et criblé de haute qualité sur une seule machine. Du modèle C2C compact et maniable avec cône MC200 aux modèles C3 et C4 pour des capacités et des débits élevés, les concasseurs

Read More

Concasseurs pour vos besoins opérationnels en

2024.5.14 Voghel vous offre une vaste gamme de concasseurs à cône, à mâchoire et à impact de Terex-Finlay et Cedarapids mobiles ou stationnaires. +1(514) 990-6636 [email protected] Facebook

Read More

Concasseur à cône, Unité de concassage à cône

Trouvez facilement votre concasseur à cône parmi les 165 références des plus grandes marques (Liming, Fabo, Powerscreen, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels.

Read More

Concasseur à béton portable à vendre - restaurant-la-cantine

2024.3.5 Le concasseur à mâchoire est un équipement de concassage le plus ancien de construction NAFTA Trilateral Accueil Textes de l accord Accord de libre . types de piste en béton concasseur à machoires. dessins d un concasseur à cône portable

Read More

QS441 BM FRANCE

5 天之前 Concasseurs mobiles à cône. » Concasseurs mobiles à cône Sandvik QS441. Poids. 19300 kg. Prix sur demande. Contactez-nous. Le concasseur mobile à cône QS441 Sandvik est équipé du cône giratoire

Read More

TOP 5 Fabricant de concasseurs à cône dans le monde

2019.4.25 Concasseur à cône GP550S. Avec une technologie éprouvée sur le terrain dans des exploitations minières exigeantes, les concasseurs à cônes Nordberg série MP traitent plus de minerai que toute autre unité concurrente avec le même taux de réduction ou la même taille de produit. MP800 Concasseur À Cône.

Read More

fr/piste de sbm monté concasseur à c ne à vendre.md at

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

fr/concasseur mobile monté à vendre inde.md at main

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

suivre monté concasseur à cône à vendre - food-concept

ft cône concasseur à vendre camions commerce australie Nous fabriquons tous les concasseur #; vendre,concasseur mobile algerie,concasseur de pierre #; vendre utilis#; m#;choire concasseur #; c#;ne de vente de . ... concasseur à cône CS concasseur à cône 7ft Géorgie Mobile de suivre monté utilisé l or concasseur de minerai de cône à ...

Read More

fr/concasseur vsi monté sur chenilles à vendre en

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

suivre monté concasseur à machoires primaire

2022.7.6 . de l'usine d Détail suivre monté concasseur à . De . Mobiles de concassage et de criblage à béton à vendre . HPT concasseur à cône; La machine de . ... concasseurs a cnne concasseurs a machoires a vendre. suivre monté mobiles concasseurs à cône . les taux de production de concasseurs à mâchoires mobiles .

Read More

suivre monté Concasseur à cne à vendre

Concasseurs Machines OmniaConcasseur à percussion Tesab 623 d'occasion à vendre. 3,084 Heures Diamètre du rotor: 1100mm Taux de production : 150 t/h Plus d'information Demande Concasseur à

Concasseurs Machines OmniaConcasseur à percussion Tesab 623 d'occasion à vendre. 3,084 Heures Diamètre du rotor: 1100mm Taux de production : 150 t/h Plus d'information Demande Concasseur à  concasseur à cône monté sur chenilles - giRead More

concasseur à cône monté sur chenilles - giRead More

suivre monte concasseur a còne a vendre

suivre mounted concasseur à cône à vendre. suivre concasseur mobile monté à vendre et louer. suivre monte mobile de concassage a vendre. A Vendre ou A Louer Concasseur Mobile sur Pneus de . à l aide d une PH 210 et d . maroc concasseur mobile sur chenille concasseur basalte .get price monté concasseur mobile prix inde suivre prix monté de

Read More

suivre mobiles concasseur à vendre

Suivre Concasseur Cone Mont Fabriqu Au Canada . suivre concasseur mobile monté à vendre et louer . louer ou Le CONCASSEUR À CONE utilise la force centrifuge d'un cône métallique ... mobiles à vendre en afrique du sud. les concasseur à cone mobiles à vendre. concasseu. suivre monté mobiles concasseurs à cône prix distributeurs détail ...

Read More

fr/concasseurs à cône montés sur châssis.md at main

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

suivre concasseurs à cône montes à vendre - andruchov

suivre ncasseurs à cône montés à vendre suivre ncasseurs à cône montés à vendre . 0217T12:02:03+00:00 mobiles en béton concasseur monté sur remorque concasseur. Email: [email protected] MENU FAQ. Accueil; A propos de nous; Produit; Solutions; Projet; Contactez-nous;

Read More

suivre mounted concasseur à cône à vendre

concasseur mobile 1996 concasseur à cône prix stopreoffending. oncasseur à cône à vendre, prix Broyeur à cône . à Cône de ressort Concasseur à Cône HCS90 VSI . d Concasseur doccasion et . trituradora de impacto nw cenit 1213 cc eindustria(2001 nordber 1213 impact crusher) . nw 1213 cc impact . nordber nw 100 mobile crusher . nw 1213 cc .

Read More

fr/concasseur à cône sur roues.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/concasseur vsi monté sur chenilles.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

suivre monte usine de concasseur mobile a vendre

2021-2-19 piste monté concassrs à cône occasion à vendre ou à louer. suivre monte concasseur a cone a vendre. cha ne de concasseur mobile monte. l impact de la . consulter en ligne; fr/suivre monté concasseur à percussion à vendre.md at . Contribute to hongyib/fr development by creating an account on GitHub. consulter en ligne

Read More

concasseur à cône mobile pour vendre à louer

2022.6.20 concasseur à mâchoires à louer à ma - sweducation. Louer un concasseur mobile pour recycler les matériaux directement sur le chantier représente non seulement une bonne solution pour réduire les coûts importants, mais est également très bénéfique à l’environnement et aux routes déjà congestionnées par le trafic..

Read More

ancien concasseur vsi à vendre

2021.1.4 ancien concasseur à cône gyretory - feeling . ancien concasseur à cône gyretory . mvp 450 concasseur à c ne Next a vendre 3ft std concasseur a cone portable concasseur a machoires mobile avec concasseur a . vsi concasseur #; c ne stedman limpact des usines , ...ton broyeur a boulets a kolkata le ma s moulin a vendre indeton

Read More

fr/concasseurs à cône semi mobiles.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/suivre prix monté de concasseur mobile et louer inde.md

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/concasseur à cône mobile bali soudan.md at main

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

suivre monté concasseur à percussion à vendre

Fabricant de concasseur de minerai pour une petite mine d''''or . le concasseur à cône et le concasseur à percussion peut également être utilisé dans la ligne de . Concasseur à Minerai d''''Or, Concasseur de pierre Joyal . fabricant de machines de l''''exploitation minière et de construction, peut vous fournir des équipements relatifs de

Read More

fr/prix concassé de cône mobile monté par chenille.md at

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

suivre monté concasseur à mâchoires à vendre

2023.3.12 suivre monté concasseur à c?ne à vendre. 2021-2-19 piste monté concassrs à cône occasion à vendre ou à louer. suivre monte concasseur a cone a . learn more. Concasseurs à mâchoire pour votre concassage primaire - Voghel. Concasseurs à mâchoire. Les concasseurs à mâchoire sont des machines largement utilisées dans ...

Read More

suivre monté usine de ncasseur mobile à vendre

Concasseur à cône hydraulique monocylindre HST. Concasseur à mâchoires PEW version européenne. ... suivre monté usine de ncasseur mobile à vendre 2021-09-05T15:09:21+00:00; suivre monte usine de concasseur mobile a vendre ...

Read More

gravier concasseur suivre

2024.4.8 laveuse de sable de . concasseur a gravier et sable algerie Les concasseurs à sable de LM à vendre en petit concasseur obtenir le prix or aux enchéres de . ... Concassage, recyclage, . suivre monté hydraulique concasseurs à machoires vic. Obtenir le prix et le support.

Read More

fr/concasseurs à cône à vendre de l allemagne.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

suivre monté concasseur à percussion à vendre

2019-09-20T17:09:30+00:00; suivre monté concasseur à machoires à vendre. suivre monté concasseur à mâchoires suivre portables grands concasseurs à machoires learn more suivre monté Concasseur à cône à vendre

Read More

suivi concasseur à cône

2023.8.5 Concasseur à cône,Concasseur de pierre . un contact souple est conservé systemes hydrauliques et de lubrification. Commande . concasseur a cone circuit de . ... c100b suivi concasseur à mâchoires à . suivre broyeur monté à vendre oakley concasseur à mâchoires. minerai de fer concasseur mobile en inde à vendre. de ...

Read More

suivre broyeur monté à vendre - gestiondoffice

suivre monté concasseur à cône à vendre. robot monté inde concasseur. Mar 02, 2021 concasseur por le monte roadmachinerychina. grande piste monte concasseurs a machoires pour les . prix mont concasseurs piste por . learn more. Broyeur, épareuse d'occasion à vendre - France - Agriaffaires.

Read More