prix du calcaire concasseur usine de lunite POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- stone crusher supplier vendre

- poudre de pierre et de sable qui est le meilleur pour la construction

- pierre de sable de concassage granulats portable

- comment le travail concasseur

- concasseur à rouleaux d où le matériau

- deuxieme main horizontale a vendre broyeur a boulets

- comment le dépistage de l usine de concassage

- fonction de broyeur à cru vertical

- broyeur palettes occasion

- afrique ecrans vibrants occasion du sud

- comment voulez vous separer le sel de sable

- parties du broyeur a boulets

- co251t d xploitation d ne broyeur

- usines primaires de concassage secondaire et tertiaire

- iron ore crusher plant design

concassage et criblage de carriere

Crushing characteristics and performance evaluation of iron ore

2023.12.1 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation parameters (eccentric speed, closed side setting and eccentric angle) on the crushing process, macro-/microscopic characteristics, corrections, and the corresponding mechanisms have been ...

Read More

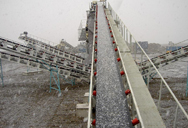

Application of Mobile Primary Crushing and Belt

2024.5.1 hopper size and design. In iron ore mining, the abrasive nature of the ore normally allowsonlycrushersthat workoncompressiveprinciples tobe used, either the jaw or gyratory type. Figure 7 shows a typical primary Lokotrack crushing plant equippedwithgrizzlyfeeder,jawcrusherandproductdischarge conveyor. Also a connection

Read More

CRUSHING PLANT PROCESS OPTIMISATION

2024.5.1 before the crusher and thereby fed to the crusher again to be re-crushed. Parts of the rock material will thereby pass the crusher more then once. The two types of stages have some fundamental differences that affect the design of the crushing plant both in terms of technical performance and cost of operation.

Read More

Tribological study of fourth-stage crusher coatings applied in an iron ...

2023.12.1 In iron ore processing plants, crushers are used to perform comminution up to a defined range for the next stage of the process, grinding. It is very common to use tapered crushers, and the crushing occurs within a cavity called the chamber, whose capacity is defined by the distance between the concave and the mantle.

Read More

Mobile crushing and Screening Plant Applications for

2020.6.22 of crusher is usually used with soft and non-abrasive material such as coal, limestone, gypsum or soft metallic ores. A typical iron ore fines crusher flow sheet is shown in Figure 1, using a high-capacity sizer as a primary crusher followed by screening and cone crushers. HiStorY Batch crushing plants

Read More

Mine Planning and Optimisation Techniques Applied in an Iron Ore

2019.11.30 The iron ore mine uses a geoscan which uses a multi-detector array and spectrometer electronics combined with gamma rays into a spectrum to determine the iron composition. The geoscans are placed on the conveyor belts that transport ore from the crusher to the plant.

Read More

Design of a crushing system that improves the crushing

2016.2.10 The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore. Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing. To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers

Read More

Simheuristic-based decision support system for

2020.9.1 For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m. In the quaternary crushing stage, the size of the ore that feeds the crushers is less than 20 mm. Screens classify the ore by size and therefore divide the flow of ore among the stages.

Read More

Optimization Framework for Crushing Plants - Chalmers

Gothenburg, Sweden 2019 Optimization Framework for Crushing Plants. KANISHK BHADANI. KANISHK BHADANI, 2019. Licentiate thesis at Chalmers University of Technology Report no. IMS-2019-10. Department of Industrial and Materials Science Chalmers University of Technology SE-412 96 Gothenburg Sweden Telephone + 46

Read More

Iron Ore Crushing Line > Ore Crushing > Solutions

2024.4.22 DSMAC Iron ore crusher plant Project Department can offer the service as follow: Turnkey general contracting service of Iron ore crushing production line project (Design, Civil Engineering and

Read More

Crushing Screening Plant Design Factors - 911

2016.4.14 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because of the use of the forced

Read More

en/119/iron ore mobile crusher with special design.md at

Contribute to dinglei2022/en development by creating an account on GitHub.

Read More

Simheuristic-based decision support system for

2020.9.1 The processed ore size defines the type and position of each stage. For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m. In the quaternary crushing stage, the size of the ore that feeds the crushers is less than 20 mm. Screens classify the ore by size and ...

Read More

Mobile Crusher Indonesia - Easy Movement - Tire Or Crawler

14 小时之前 Crawler Mobile Crusher – Crushing And Screening – Integrated design. Materials processed: Limestone, granite, marble, basalt, iron ore, river pebbles, construction waste, etc. Application areas: It is suitable for producing natural stones of medium and soft hardness, the recycled aggregate of construction waste, etc.

Read More

How to design an iron ore processing facility with crushing

2023.3.20 Design the layout of the processing facility based on the chosen methods of crushing and beneficiation. 4. Create a test plan to ensure that the design meets the required production requirements ...

Read More

crusher plant iron ore in indonesia - LinkedIn

2023.10.30 Transforming Iron Ore Mining in Indonesia with Advanced Crusher Plants Introduction: Indonesia, a Southeast Asian archipelago, boasts a rich reserve of iron ore, making it a promising resource for ...

Read More

Cement Crusher – Crusher In Cement Plant AGICO Cement

Hammer Crusher Impact Crusher. These two crushers are based on the impact principle of material crushing, with coarse crushing, medium crushing and fine crushing three types. Their main difference mainly lies in the broken part. The former uses the hammerhead hinged on the rotor, while the latter uses the blow bar embedded on the rotor.

Read More

China Jaw Crusher Manufacturer, Hammer Cruser, Cone Crusher

China Jaw Crusher Supplier, Hammer Cruser, Cone Crusher Manufacturers/ Suppliers - Henan Fuyuan Machinery Manufacturing Co., Ltd. ... Mobile Stone Iron Gold Ore Rock Mining 100-150 Tph Jaw Crusher Manufacturers Price Portable Granite Crushing Machine Plant for Sale. US$8,960.00-29,646.00 / Set. 1 Set (MOQ)

Read More

Crushing - Metso

Metso is combining our legacy and expertise to introduce the Mining Crushing Stations. These 2 modular crushing and screening plants are unique, cost-efficient and productive, and designed to provide significant time and resource savings. The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations.

Read More

Setting up of crushing plant: design and layout

2014.8.21 Design parameters. The principal design parameters that drive crushing plant selection and configuration include production requirements, capital expenditure and operational expenditure, ore

Read More

Pre-Feasibility Report

2021.7.8 1 Crushed Washed Iron ore (Iron ore crushing and Beneficiation plant 1.6 MTPA 2 Pellets Plant along with 48000 Nm3/Hr coal gasifier 1.2 MTPA (2X0.6 MTPA) 3 Sponge Iron Plant (1X350 TPD DRI plant) 2,31,000 TPA 4. Power Generation (WHRB) 16 MW (2X8 MW) 5 M.S. Billets (Induction Furnace

Read More

en/166/can i design an iron ore crusher.md at main lbsid/en

Find and fix vulnerabilities Codespaces

Read More

Application of Mobile Primary Crushing and Belt

2024.5.1 Iron Ore Conference Perth, WA, 20 - 22 August 2007 311 1. ProductManager,LargePrimaryLokotrackPlants,MetsoMinerals, Tampere, Finland. Email: jorma.kempas@metso FIG1 - Mobile primary gyratory crusher. FIG2 - Track-mounted three-stage crushing plant.

Read More

crushing,screening and washing plant for iron ore Mobile Crusher ...

2012.12.31 In iron ore coarse crushing plant, jaw crusher is often to be selected, in medium crushing process, processer usually use impact crusher, and in the fine crushing, short-head type cone crusher is suitable. iron ore screening plant ... combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed ...

Read More

Crushing Plant - an overview ScienceDirect Topics

Developments in iron ore comminution and classification technologies. A. Jankovic, in Iron Ore, 2015 8.2.4 Mobile crushing and screening plant applications for small- to medium-sized iron ore projects. There is now a new generation of mobile crushing and screening plant systems, which have been developed based on the motivation of reducing truck haulage.

Read More

Crushing characteristics and performance evaluation of iron ore

2023.12.1 1. Introduction. Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al., 2014).The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to

Read More

Iron Ore Processing Plant in Ethiopia - ZENITH Crusher

6 天之前 Iron Ore Processing Plant in Ethiopia. ... Typically, main types of iron ore mining equipment in Ethiopia includes the iron ore crusher machine, iron ore grinding mill and iron extraction equipment. ... The Magnetic Separators are available in cyclic design with process vessel diameters smaller than 3mm. Its magnetic system is a ring-shape ...

Read More

Comminution and classification technologies of iron ore

2022.1.1 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

Read More

Crushing Plant Design and Layout Considerations - JXSC Mine

1 Considerations of stone crusher plant design. ... For example, the feeding of the autogenous mill is 300 to 500 mm, the particle size of the iron-rich ore smelting in the blast furnace is divided into two stages of 25 ~ 30 and 25 ~ 30 mm. The reasonable ore size of the rod mill is 20 ~ 40, the ball mill has a reasonable ore size of 10 to 25 mm.

Read More

Iron Ore Beneficiation Plant Equipment For Mining Process

2023.9.4 The complete plant consists of the below machines: vibrating feeder, jaw crusher, belt conveyor, cone crusher, double roller crusher, vibrating screen, dry magnetic separators, and ball mill. Raw ore information as below: Iron rock ore, magnetite Fe3 O4. Rock after crushing to 5mm for release inside the iron.

Read More

crusher/sbm iron ore using crushing plant.md at main

Contribute to yunan88/crusher development by creating an account on GitHub.

Read More

Impact Crusher - Impact Rock Crusher AGICO

Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive

Read More

Iron Ore Processing

The grade of iron ore refers to the mass fraction of iron element in iron ore, say, the iron content. For example, if the grade of iron ore is 62, the mass fraction of iron element is 62%. Through crushing, grinding, magnetic separation, flotation separation and re-election, the iron can be selected from the natural iron ore.

Read More

Small Portable Crusher Plant - JXSC Machinery

4 天之前 Portable Jaw Crusher plant. Capacity: 1-1120t/h. Configuration: feeder + jaw crusher + belt conveyor. Applicable Materials: quartz, granite, basalt, limestone, cobblestone, iron ore, copper ore, dolomite, calcite, etc. Process: The feeder quietly but efficiently supplies a steady stream of raw material to the primary crusher.

Read More

What Machines Do Stone Crushing Plants Need? Fote

2024.3.1 2. Gyratory crusher. A gyratory crusher is one of the most in-demand primary crushers for stone crushing plants. It can process rocks, metal ores, granite, and other solid minerals of medium to high hardness. Gyratory crushers may be huge and capital-intensive, but they excel in high-capacity operations.

Read More

Mine Planning and Optimisation Techniques Applied in an Iron Ore

2019.11.30 The ultimate pit design for the iron ore mine was created in Surpac and is currently being used as a reference in the long term, medium term and short-term planning. The ultimate pit is approximately 4.3 km in length and 1 km wide. ... The geoscans are placed on the conveyor belts that transport ore from the crusher to the plant. The

Read More

Sinter Plant Presentation (Sinter Operation) - [PDF Document]

2015.10.13 Sintering process caught attention of steel plant managers around the world to take care of waste generated in the steel plant and the fines generated in the mines. Plant Commissioning Details Plant Capacity : 2.24 Million tons Per Annum @ 6653 tpd with 337 working days. Date Of Commissioning : 15th December 2005. Plant Equipment

Read More

Dense Media Separation (DMS) Plants - JXSC Machine

2024.5.14 Dense Media Separation. A heavy medium is a heavy-fluid or heavy suspension fluid with a density greater than that of water (1g/cm3). The process of separating ore particles in heavy media is called Dense Media Separation / Heavy Media Separation (DMS / HMS). The heavy medium separation method is an advanced gravity

Read More

Iron Ore Beneficiation Plant - JXSC Machinery - Mineral

4 天之前 2. The jaw crusher crushes 50-230mm iron ore into the fine jaw crusher. Spiral washing machine is suitable for cleaning 0-50mm materials. 3. The fine jaw crusher crushes the material to 0-20mm. The vibrating screen sends the 0-20mm material into the ball mill, and the +20mm material returns to the fine jaw crusher.

Read More