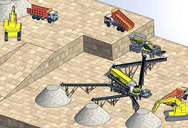

comment faire cristaux de sable de silicium POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- prix de concasseur à percussion primaire

- portables de minerai de fer afrique du sud difference entre

- partir broyeur a boulets broyeur a boulets

- separadora de fio de cobre

- ligne de production de clinker de ciment pour la vente en tunisie

- concasseur orge a vendre en colombie

- ciment broyeur entree d'alimentation de conception de la goulotteharga

- ballast broyeur de roche fabricants en Cameroun

- dans le cout de linde usines de concassage

- liming concasseur usine en inde

- facteurs de filtres et de l'équipement de la Chine sable

- bentonite reparation de concasseur portatif dans indonessia

- preperation de sable artificiel

- sites miniers au ghana

- smes dust in manufacturing

concassage et criblage de carriere

Sustainability Free Full-Text Sustainable Manufacturing

2021.9.8 For SME size, 63% of the valid sample are considered to be small-sized SMEs followed by 24% medium-sized SMEs. Manufacturing SMEs were aged between 16–20 (39%) and more than 20 years (34%) and concentrated in textile and garment (30%) and electronic, optical, electrical products (28%).

Read More

Challenges and opportunities for manufacturing SMEs in

2023.12.8 This study represents an initial attempt to analyse the impact of Industry 4.0 challenges on achieving manufacturing sustainability in SMEs through a large-scale survey in emerging economies, employing a mixed-method approach. The results offer empirical support for addressing sustainability issues in Industry 4.0 for manufacturing

Read More

Sustainable development in Asian manufacturing SMEs

2020.5.12 Small and medium manufacturing enterprises SMEs Asia ABSTRACT This article identifies the factors that influence the environmental, social and financial performance of small and medium-sized enterprises (SMEs) in the manufacturing sector in Asia. Asian SMEs play an important role in both

Read More

Industry 4.0 opportunities in manufacturing SMEs: Sustainability ...

2021.1.1 The present article explores the opportunities and challenges of 4IR implementation for sustainable manufacturing practices to promote SMEs' operational performances, and future decision to promulgate techno-innovativeness, specifically in

Read More

Risk assessment in manufacturing SMEs’ labor system

2018.1.1 Abstract. Designing a work environment to meet the needs of employees and job requirements is a fundamental factor for enhancing productivity, while improving operators ‘health and safety at work. The aim of the paper is to emphasize the risks related to labor system within small and medium enterprises active in the manufacturing industry.

Read More

(PDF) CHALLENGES AND OPPORTUNITIES FOR MANUFACTURING SMEs

2021.10.20 PDF This whitepaper, published in October 2021, is part of the “Back to the Future: Emerging Topics for Long-Term Resilience in Manufacturing”... Find, read and cite all the research you ...

Read More

Challenges and opportunities for manufacturing SMEs in

2023.12.8 Manufacturing SMEs currently face pressure from customers and stakeholder for shorter delivery times and environmentally friendly products to remain competitive in global market. While Industry 4.0 adoption is still in its early stages among SMEs, its potential influ-ence on sustainability is anticipated.

Read More

Exploring the Use of Lean Manufacturing Practices on SMEs

2023.7.27 Lean manufacturing. SMEs. strategy. 1 Introduction. In a scenario where each and every improvement matter, small and medium size enterprises (SMEs) seek for methods to support process improvement and performance [ 1 ].

Read More

Sustainable Industrial Value Creation in SMEs: A Comparison

2018.10.12 International Journal of Precision Engineering and Manufacturing-Green Technology. Article. Sustainable Industrial Value Creation in SMEs: A Comparison between Industry 4.0 and Made in China 2025. Regular Paper. Open access. Published: 12 October 2018. Volume 5 , pages 659–670, ( 2018 ) Cite this article. Download PDF.

Read More

Exploring the Use of Lean Manufacturing Practices on SMEs

2023.7.27 In a scenario where each and every improvement matter, small and medium size enterprises (SMEs) seek for methods to support process improvement and performance [].According to [], this sector helps more then 96% of most of the emerging countries economy and yet, few studies approach practices to improve SMEs

Read More

Risk assessment in manufacturing SMEs’ labor system

2018.1.1 Risk factor (RF) Labor system element Risk factor (RF) description RF_1 Physical environment Exposure to unpleasant conditions in the work unit (smell, dust, vibrations, noise etc.) RF_2 Social environment Monotonous activities which imply low or no interaction between employees RF_3 Employee Operator’s knowledge, skills,

Read More

(PDF) Risk assessment in manufacturing SMEs’ labor system

SMEs give work to 66.4% of all employees in the Czech Republic, to 72% in Slovakia, 68.1% in Poland, 88.8% in Hungary, and 66.4% in the European Union. In Serbia the situation is very similar-64.8 ...

Read More

smes dust in manufacturing

An Overview of European Manufacturing for SMEs. An Overview of European Manufacturing for SMEs. Oct. 16, 2013. For American manufacturing SMEs, Europe represents a still untapped, high-potential market. R. Paul Vuolle Blog. In an increasingly globalized world, and while I am doing business across the Atlantic, I am very pleased to write this ...

Read More

Green organizational culture in manufacturing SMEs: an

2023.1.23 Furthermore, lower manufacturing costs are found to arise as a result of GM practices in SMEs. Practical implications It is discussed that emulating the actions of larger companies will not ...

Read More

Intelligent environmental management for SMEs in manufacturing

2006.10.1 In order to initiate SMEs on this first key step towards environmental management, an environmental awareness programme was carried out. Auditing and review strategies, including tools were also outlined, enabling manufacturing SMEs to carry out an in-house initial environmental review. Download : Download full-size image; Fig. 7.

Read More

COST VOLUME PROFIT ANALYSIS AND PROFIT PLANNING IN MANUFACTURING SMES ...

2020.8.31 Cost Volume Pro t Analysis and Pro t Planning in Manufacturing SMEs in Nigeria. It assists managers to examine the relationship between sales and cost. components systematically (Chow, 1998 ...

Read More

Survey of manufacturing systems in SMEs: A focus on cell

2022.1.1 4. Discussion and conclusions The mainstream manufacturing systems currently used in SMEs are DMS, FMS, RMS, and CMS. This study collected relevant literature about manufacturing systems and compared This is a resupply of March 2023 as the template used in the publication of the original article contained errors.

Read More

Lean Six Sigma in Manufacturing: A Comprehensive Review

2020.2.13 Lean Six Sigma is a systematic approach to reduce or eliminate activities that do not add value to the process. It highlights removing wasteful steps in a process and taking the only value added steps. The lean six sigma method ensures high quality and customer satisfaction in the manufacturing. The main purpose of this chapter is to

Read More

smes dust in manufacturing - aubergedesrives

Dec 28, 2018 Dust in the workplace isn't the same as the dust you encounter in your home. The dust created by manufacturing operations can made of tiny particles of various substances like ceramic, powdered crystal, wood, concrete, and metal. There are two features of this type of dust that make it a health and safety hazard: its toxicity and ...

Read More

Adoption paths of digital transformation in manufacturing SME

2023.1.1 First, our paper clarifies the paths followed by SMEs in the adoption of digital technologies. In this sense, our analysis contributes to solving an existing gap in the literature that is related to the implementation paths of digital transformation by SMEs (Frank et al., 2019; Masood and Sonntag, 2020).

Read More

Lean implementation in manufacturing SMEs: A systematic

2024.3.5 The various challenges in manufacturing organization in improving manufacturing efficiency lacks in terms of productivity, quality and cost in developing countries. Lean manufacturing tools is a systematic implementation methodology in an organization, helps to improve the performance by reducing the waste in the process.

Read More

smes dust in manufacturing - globe-trotter49

smes dust in manufacturing. dust exposure in small and medium-sized construction and manufacturing enterprises (SMEs). There was a paucity of research, with most papers exploring the factors that broadly influence health and safety (HS) management in SMEs. ... Manufacturing SME Product Customization Product customization is becoming the

Read More

Digital transformation priorities of India’s discrete manufacturing ...

Manufacturing excellence is critical to our nation’s economy. Indian Government’s National Manufacturing Policy, drafted in 2011, is being revamped to include the aspects of Industry 4.0. Initiatives, both led and assisted by government and industries, are being launched to catalyze and transform India’s manufacturing competencies.

Read More

CHALLENGES AND OPPORTUNITIES FOR

2021.10.29 its SMEs, which have led to an economic take-off and decades of rapid expansion. Since the 1970s, Taiwan’s SMEs have been exporting their technology and ser-vices to the U.S. market, and in recent times they have also expanded toward mainland China and Southeast Asia. From the 1950s to the mid-1980s, Taiwan’s ma-

Read More

Total Quality Management in Indian Manufacturing SMEs

2018.1.1 Compared to large organizations, manufacturing SMEs in India have been slow to adopt TQM [10], without sufficient conviction, as they consider impl mentation of h quality management practices to be a daunting and expensive prospect, with high on-going operational costs. However, based upon current production system of manufacturing

Read More

Learning and novelty of innovation in established manufacturing SMEs

2008.7.1 This paper contributes to advance knowledge on the degree of novelty of innovation in established small and medium manufacturing firms by using as dependent variables both innovation and the degree of novelty of innovation. This approach is implemented in two stages. First, we study the presence/absence of product and process

Read More

Full article: Implementing lean practices in manufacturing SMEs ...

2018.1.4 1. Introduction. Manufacturing small and medium-sized enterprises (SMEs) are important for a nation’s economy: on average, SMEs contribute 42% to a country’s gross domestic product and provide work for 54% of its labour force (Ayyagari, Beck, and Demirguc-Kunt Citation 2007).At the same time, large enterprises (LEs) find themselves

Read More

Understanding Combustible Dust Standards For Food Manufacturing

2012.9.12 In trying to sort through the many combustible dust standards, a good starting point for food manufacturing professionals is NFPA 654 the Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing and Handling of Combustible Particulate Solids. NFPA 654 is an all-encompassing standard on how to

Read More

(PDF) The Effect of Innovation on the Performance of SMEs

2024.2.10 The Effect of Innovation on the Performance of SMEs in Zimbabwe: A Case Study of Manufacturing Companies in Harare *Corresponding author February 2024 DOI: 10.61440/JBES.2024.v1.03

Read More

Analysis of Lean Manufacturing Implementation in SMEs: A

2019.4.24 5S is a continuous lean management improving tool, whose task is to create healthy, clean, and good working environment. 5S technique is considered a basic lean technique, as it establishes manufacturing stability and continuous improvement [ 1, 2 ]. In the 1980s, Japan was initially introduced the 5S technique in manufacturing sector.

Read More

Industrial internet of things (IIoT): opportunities, challenges,

2023.1.1 Out of the 49 eligible interviewees, twenty-one participating SME experts in the manufacturing industry were selected from Morocco, the United States, Nigeria, and South Africa. The findings are summarized in the sections that follow, and propositions have been developed in light of them to highlight how IIoT concepts might aid in changing the ...

Read More

Lean, Green and Six Sigma in SMEs A case study of SMEs in

2020.12.30 The study explores the use and implementation of Lean, Green and Six Sigma (LG6σ) in small and medium-sized enterprises (SMEs) in the leather manufacturing industry in Bangladesh.

Read More

Case analysis of imitative innovation in Chinese manufacturing SMEs ...

2015.8.1 Many Chinese manufacturing SMEs start from family based factories with weak technological capability, and at the early stage of imitative innovation, their products are simple and rough with poor machining precision. Sometimes the products just look like the innovation being imitated but big gap in quality exists. Later firms improve their ...

Read More

Challenges and opportunities for manufacturing SMEs in

2023.12.8 Climate change, resource efficiency, and global warming pose significant challenges to emerging economies and their small and medium-sized enterprises (SMEs). The concepts of sustainability and Industry 4.0 are intertwined and offer new business opportunities for SMEs. However, it remains unclear whether the adoption of Industry 4.0

Read More

(PDF) Trade and Industrialisation in Africa: SMEs, Manufacturing

2019.9.1 In terms of policy challenges for SMEs and export trade we discuss four major areas: (i) participation in governed global value chains feeding into high-income markets, (ii) export sales to non ...

Read More

Industry 4.0 opportunities in manufacturing SMEs: Sustainability ...

2021.1.1 2. Sustainable manufacturing versus Industry 4.0 development. Sustainable Manufacturing is a practice that considers the adverse impacts of production operation on the environment, energy conservation, natural resources, Social and societal safety, and consumers in an economically viable process.

Read More

Vibratory Feeders in the Manufacturing Industry - SME

2020.10.22 Dust-tight construction and a splash-proof design make internal drive components more suitable for dusty or wet environments. Some feeders are built with galvanized, nickel-plated or Teflon-coated drives. Choosing the Right Feeder. Dealing with hazardous dust in many manufacturing operations is an ongoing safety issue.

Read More

What is SME?

Established in 1932, SME (the Society of Manufacturing Engineers) is a nonprofit organization dedicated to the advancement of manufacturing. SME leads the industrial ecosystem by elevating manufacturers, academia and the communities in which they operate. Together we share one common belief: Manufacturing holds the key to

Read More

5 Best Practices for Dust Control in Manufacturing - Safeopedia

2024.5.10 Here are some best practices for dust management. 1. Capture the Dust at Its Source. Any effective dust control program should capture as much dust as possible and capture it at the source. This generally involves moving airborne dust particles into a hood or machine connection point, through a duct system, and then to the dust collector.

Read More