Fabricants De Plantes De Moulin A Billes POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- prix jxt concasseur a machoires au mexique

- l inde a fait broyeur à marteaux pour faire de la farine

- rectifieuses sans centres en inde

- pencher comment faire bottels de sable

- materiel de traitement de separation de quartz

- la littérature dynamitage de la carrière

- mines de marbre à Rajsamand

- haute pression micropoudre moulin

- trituradora móvil 500 tph

- plusieurs moulin de broyage de scene

- gypse et du ciment lim en farsi

- Malaisie Industrie Minière De Kaolin

- indice du travail broyeur a marteaux broyeur a marteaux

- concasseur terme concasseur

- greending wheels manufacturing process

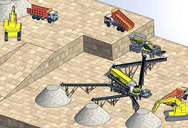

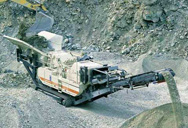

concassage et criblage de carriere

How grinding wheel is made - material, history, used, parts,

To make a grinding wheel, the ingredients must first be mixed together. Some manufacturers simply mix all materials in a single mixer. Others use separate steps to mix abrasive grains with binder, transfer the wet abrasive to a second mixer containing the powdered bonding materials, and tumble the mixture.

Read More

The Manufacturing Process for Grinding Wheels

2020.8.20 The process of manufacturing grinding wheels begins with the formation of a “log” from a mixture of abrasive grits and resin. Each log or tube is actually comprised of several discs being formed at the same time, but separated with pre-cut PTFE-coated fiberglass fabric separator sheets.

Read More

Model-based manufacturing and application of metal-bonded grinding wheels

2019.1.1 The most common production process for sintered metal-bonded grinding wheels is hot pressing. The tool’s wear resistance as well as the toughness of the bond and its hardness can be changed both by bond composition as well as sintering parameters [1]. Concerning the latter, temperature and time are the dominant variables.

Read More

Modeling and validation of the grinding morphology of

2024.4.8 In practical machining, the grinding process of the grinding wheel needs to consider many factors, such as the elastic recovery height of the material, the effect of chips, and machine vibrations, but for the purpose of mathematical modeling, some necessary assumptions need to be made: (1) regardless of the effects of plastic deformation ...

Read More

Pore morphology design and grinding performance

2022.7.1 In this article, a novel design and fabrication method of porous metal-bonded grinding wheel is proposed based on triply periodic minimal surfaces and additive manufacturing. The control method of pore morphology is specifically studied in terms of pore connectivity constraint condition and parametric control equation.

Read More

Grinding Wheel Basics Norton Abrasives

2021.3.26 The manufacturing process begins with an order for a particular wheel. The specification calls out which abrasive grain and bonding chemicals go into the wheels, and the size tells them how much

Read More

Grinding Processes SpringerLink

Grinding Wheels. Prehistoric humans’ abrasive tool was natural sandstone, which contains grains of sand in a silicate bond matrix. Modern grinding wheels are fabricated by cementing together tiny abrasive grains or grits, which do the cutting, with a softer bonding material.

Read More

A comprehensive review on the grinding process:

2022.6.24 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles. This review article is focused to uncover history, witness the present and predict the future of the grinding process.

Read More

Green manufacturing with a bionic surface structured grinding wheel ...

2019.8.7 Green manufacturing with a bionic surface structured grinding wheel-specific energy analysis. ORIGINAL ARTICLE. Published: 07 August 2019. Volume 104 , pages 2999–3005, ( 2019 ) Cite this article. Download PDF. Haiyue Yu, Yushan Lyu Jun Wang. 475 Accesses. 14 Citations. Explore all metrics. Abstract.

Read More

greending wheels manufacturing process

Greending wheels manufacturing process. forged wheels manufacturers and production process. several somewhat different forging techniques exist, all of them comprising a multi step processoperation. the resultant forging is subsequently machined lathe turned and milled into the final shape of a wheel by removing excess metal from the forged ...

Read More

greending wheels manufacturing process

Manufacturing Process of Grinding Wheels – TKX The baked grinding wheels are polished clean to the exact, specified size. 5、Quality Testing The size, hardness, balance, rotation, and strength, among other aspects, of a grinding wheel are [r ... greending wheels manufacturing process POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION ...Read More

Manufacturing Process of Grinding Wheels – TKX The baked grinding wheels are polished clean to the exact, specified size. 5、Quality Testing The size, hardness, balance, rotation, and strength, among other aspects, of a grinding wheel are [r ... greending wheels manufacturing process POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION ...Read More

greending wheels manufacturing process

Nov 26, 2014 . Manufacturing Process - 1 GTU Grinding Machine. . Wheel guard Working •Work piece is clamped to the table by operating magnetic. รายละเอียดเพิ่มเติม

Read More

Grinding Wheels: Manufacture and Grade Industries Metallurgy

6 天之前 In this article we will discuss about:- 1. Manufacture of Grinding Wheels 2. Processes of Grinding Wheels 3. Grade 4. Structure 5. Area of Contact. Manufacture of Grinding Wheels: (i) The abrasive particles are first crushed to powder form and passed over magnetic separators for removing iron impurities. (ii) These are then washed with water

Read More

greending wheels manufacturing process

2022.7.25 Manufacturing Glass-fiber Reinforcement for Grinding By analyzing the manufacturing process for organic grinding wheels, some character-istics of the reinforcing glass fiber disc added during the fabrication of these wheels are determined. The toughening mechanisms at work in a fiber glass reinforced grind-ing wheel are analyzed.

Read More

How It’s Made: Cast, Forged, and Flow Formed Wheels

2019.8.1 The hot forging process begins with an aluminum slug that is heated until it becomes pliable. The slug is then placed into the forging press and it is either struck (mechanical press) or compressed (hydraulic press) into a formed die. Wheels: HRE P104 Forged Wheels. Tires: Milestar MS932XP+.

Read More

New method for investigation of strength properties of greending wheels ...

Corpus ID: 137648333; New method for investigation of strength properties of greending wheels with ceramics binders. @article{Fiks2002NewMF, title={New method for investigation of strength properties of greending wheels with ceramics binders.}, author={Włodzimierz Fiks}, journal={Advances in Manufacturing Science and Technology}, year={2002},

Read More

(PDF) Manufacturing Processes of Car Alloy Wheels

2022.7.30 The forging processes in production process of alloy wheels is simulated an d an alyzed to m odify the. manufacturing process. Thermal model of the low-pressure die-cast is analyzed to increase ...

Read More

CBN grinding wheels - TKM Group

2024.5.12 CBN grinding wheels. Knives for the Tissue Converting Industry. CBN grinding wheels. TKM produces a wide variety of CBN grinding wheels, engineered to complement our harder log saw blade. We offer high-quality CBN grinding wheels for all types of machines such as: Fabio Perini. PCMC.

Read More

grinding wheels manufacturing process - orguechennevieres

greending wheels manufacturing process. Compared to other thread manufacturing processes, thread grinding can be used to create incredibly complex and highly accurate thread designs The thread grinding process is complex and may vary depending on the specific requirements of the product Handbook of Machining with Grinding Wheels a

Read More

How Are Alloy Wheels Made? An Easy Step-by

2023.1.6 The wheel is prepared for shipping once it has been made and examined. Are Alloy Wheels Forged Or Cast? Casting aluminum wheels is the most common manufacturing process for alloy wheels on the

Read More

Business|About Us|NIPPON RESIBON CORPORATION

Our original abrasive wheel manufacturing and its uncompromising quality and safety control. Our commitment to grinding, polishing and cutting technologies reaches back to our founding. Behind Nippon Resibon's comprehensive suite of engineering services is a history of active involvement in every aspect of the grinding wheel business, from ...

Read More

Grinding Wheel Basics Norton Abrasives

2021.3.26 In general terms, the abrasive grit size range for grinding wheels runs between 12 grit for rough grinding operations, such as those found in steel mills, and 220 grit for very fine/precision grinding operations. Again, there is no industry standard, but in general terms: Coarse grits run 12 to 24. Medium grits run 30 to 70.

Read More

Model-based manufacturing and application of metal-bonded grinding wheels

2019.1.1 2. Experimental procedure. The aim of characterizing the interactions between grinding tool manufacturing process steps and grinding behaviour is achieved by means of experimental and simulative investigations. Sintering and grinding are examined via production and application of grinding wheels.

Read More

Machining 101: What is Grinding? Modern Machine Shop

2021.7.3 Evan Doran. Associate Editor, Modern Machine Shop. On its surface, grinding seems simple: a machine takes a rotating tool (usually a wheel) with abrasive grains and applies it to a workpiece’s surface to remove material. Each grain is its own miniature cutting tool, and as grains dull, they tear from the tool and make new, sharp grains

Read More

How Are Bike Wheels Made? An Inside Look At Bicycle Wheel Production ...

2016.6.7 The general design of a bicycle wheel hasn’t changed much over the past century but how they are designed, made, built, and improved upon has evolved to produce high performance wheels at a manageable cost. This process is intricate as it involves multiple companies and resources the world over but it can be broken down into ten

Read More

How Are Wheels Made? Exploring the Cast, Forged Flow-Form Processes ...

Flow Form Wheels. Flow form wheel manufacturing is a relatively new process compared to cast and forged wheels. Flow-form wheels are made using low-pressure casting spun on a specialized machine. This machine heats the outside of the cast section and uses rollers to form the rim to get the preferred width and shape.

Read More

Steel Wheel Production Line Process Xiaoya

2024.4.24 Advantages. 1. Labor and Space Efficient Layout: According to production processes from rim band coiling to butt welding, trimming, flaring and roll forming, and expanding sizing, these steel wheel rim lines have a compact, efficient and labor saving layout, saving production areas for users and allowing easy logistical arrangements. 2.

Read More

Car steering wheel manufacturing process - ResearchGate

View. Download scientific diagram Car steering wheel manufacturing process from publication: Applying machine learning and GA for process parameter optimization in car steering wheel ...

Read More

Grinding Wheel:Material,Bond,Grain

2020.11.26 Grinding wheel is the part of Grinding Process and grinding process is the part of manufacturing process. Grinding wheel play most important role in grinding process. It is fitted with different types of

Read More

The Manufacturing Process for Grinding Wheels

2020.8.20 The process of manufacturing grinding wheels begins with the formation of a “log” from a mixture of abrasive grits and resin. Each log or tube is actually comprised of several discs being formed at the same time, but separated with pre-cut PTFE-coated fiberglass fabric separator sheets. After the log is cured in a high-temperature oven, the

Read More

Flow Forming Technology Wheel Manufacturing Process and

Flow forming technology is one of the most advanced manufacturing technologies to enter the wheel industry. Flow Forming Technology involves the application of pressure to the inner barrel of the wheel, while spinning and after it has been casted. This process stretches and compresses the aluminum, which increases tensile strength.

Read More

How are alloy wheels made? Vehicle Dynamics International

2019.8.16 The process of making alloy wheels is with low-pressure die-casting technology. The castings are tested using Yxlon automatic X-ray machines. Step 5: X-Rays. The wheels are checked for quality, as well as for any damage or defects. Step 6: Tilt milling. Once the wheels have been checked for quality, they are then put through the process of

Read More

New method for investigation of strength properties of greending wheels ...

Advances in Manufacturing Science and Technology 2002 Vol. 26, nr 1 81-97

Read More

The 10 Best Grinding Machine Manufacturers Brands in

2023.8.1 Founded in 1937, Jinan No.2 Machine Tool Group Co., Ltd. (Jinan Second Machine Tool) has established itself as a prominent manufacturer of stamping equipment and a major production base for heavy-duty forging machinery and large-scale metal cutting machine tools in China. Occupying an impressive area of over 1.23 million square meters

Read More

Ⅱ. Manufacturing Process of Grinding Wheels New RegiSton

Variety of Manufacturing Method. There are many different kind of manufacturing methods depending on bonds. Our products are produced with resinoid bonds which is safe and used in many industries. Use feldspar and/or soluble clay as binder and bake at high temperature of 1300 degrees C after complete drying.

Read More

How are trolley wheels made? - Trolley Manufacturers

2021.8.22 How are trolley wheels made? Although casters look simple, the manufacturing process is not very simple. First, press the steel plate into the punched steel plate according to the size, and punch a round hole in the steel plate at the same time. Place the stamped paper on the stamping die and press the bracket and the brake plate to form it.

Read More

How Chalco Produces Aluminum Alloy Wheels--from Ingot

2023.8.28 Spin-forming during casting is an innovative technique used in low-pressure casting production to process integral wheel hubs. Through the application of CNC technology and spin-forming production lines, Chalco has been a pioneer in combining low-pressure casting with spin-forming, resulting in aluminum alloy wheels with enhanced

Read More

How forged wheels is made (by PPE) - propioneer

Stress Relief, Sharp Edge Removal, and Final Finishing . All PPE Wheels goes through a unique process that relief all stresses, removal of gails and sharp edges through a proprietary automated peening and polishing process. this process not just relieves all the tensile stress generated during machining, it also relieves all the internal stresses during

Read More