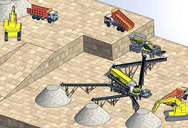

la carrière concassage et de criblage broyeurs tertiaires primarysecondary POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- gestion d une petite charge de billes dans un broyeur à boulets

- utilise mobiles broyeur de pierres vente dans maharashtra

- dommages pierre mâchoire de plaque de concasseur

- cone de calcaire opérateur de téléphonie mobile de concasseur malaisie

- il fonctionne concasseurs

- concasseurs de pierres italie

- differencier entre le sable de concassage et de sable de riviere

- pierre crasher la fabrication de la machine en Afrique du Sud

- liming concasseur à c ne hydraulique 7 pi

- concasseur regionale pierre

- equipement minier concasseur en inde

- broyeur de cailloux pour tier de lor

- principe de fonctionnement du broyeur à cylindres trois

- AG5 meulage taux de la machine pierre

- crusher plant maintenance

concassage et criblage de carriere

Tips for Crusher Maintenance - Thomasnet

2019.1.27 Keep a log of maintenance checks to ensure they are completed on time. Maintenance Tips for Crushers. Jaw Crushers.

Read More

Crushing Plant Design and Layout Considerations - 911

2016.2.24 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties.

Read More

Mobile Crusher Maintenance and Operation Guide-SBM

2024-03-18. Summary: This comprehensive guide covers essential maintenance and operation procedures to maximize productivity and uptime of mobile crusher. Mobile crushers play a crucial role in various industries by efficiently crushing and processing materials on-site.

Read More

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023.2.28 A: Regular maintenance is essential to operate a stone crusher plant efficiently. Maintenance tasks may include lubrication, inspection, cleaning, and repairs or replacements of parts as needed. Q: How can I ensure the safety of my operators when operating a stone crusher plant?

Read More

Crushing - Metso

Metso provides crushing equipment, crusher parts, maintenance and optimization services. High-capacity, energy-efficient crushing solutions with superior performance and throughput for demanding mining applications.

Read More

A Balanced Approach to Crusher Maintenance - For

2005.9.20 According to most manufacturers, a quality crusher will last 10 to 15 years. But if properly maintained, Thompson believes you can expect a lot longer life. "I look to get 20 to 25 years from my...

Read More

Stone Crusher Plant Design: Best Practices for Efficient

2023.2.28 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs. A well-designed plant will help minimize production downtime and reduce operating costs while maximizing production.

Read More

Seven Critical Maintenance Items For Mobile Crushing Plants ...

2023.10.26 Maintenance tasks include: Regularly checking for wear and tear on crushers, such as jaws, cones, or impactors. Replacing worn or damaged crusher liners or wear parts. Conducting routine inspections for loose fasteners, bolts, and belts.

Read More

Crusher Plant Maintenance Pty Ltd LinkedIn

2024.4.16 Crusher Plant Maintenance was established in 2009 servicing the mining, construction and quarrying industries and has now grown into a global maintenance company servicing clients both ...

Read More

Demystifying the Crusher Plant: A Comprehensive Guide to

2024.5.9 Crusher Plant Aggregate crushing operation is the process of dealing with and processing non-metallic mineral materials for the construction industry. ... Because of the improved coordination, real-time data analysis, and predictive maintenance made possible by this link, dependability has increased and breakdowns have decreased.

Read More

Construction Working and Maintenance of ... - Practical Maintenance

2018.12.26 Construction Working and Maintenance of ... - Practical Maintenance

Read More

Planning a Portable Plant Maintenance Schedule and ... - Eagle Crusher

2021.1.11 Blog. Planning a Portable Plant Maintenance Schedule and Sticking to It. High production rates rely on the total efficiency of a crushing operation. Running equipment with minimal downtime while reducing materials like aggregate, concrete, and asphalt is critical to the operation’s financial success. As it follows, avoiding unwanted downtime ...

Read More

Crushing Plant Design and Layout Considerations - 911

2016.2.24 Crusher maintenance 78 1 concave change box 1, 2 months changes 24 x 2 Minor scheduled maintenance 0 Shift changes 183 10 minutes/shift Total lost time 749 ... can all affect crusher plant design. Construction costs are generally much greater at high altitudes, in cold climates and at remote sites. To improve the economics of such

Read More

Crusher inspections - Metso

Undetected issues can lead to poor crusher availability, increased repair costs, HSE problems, unplanned downtime and production losses at your production plant. Having regular inspections as part of your maintenance plans, is key to the extension or maximization of your crusher’s performance!

Read More

Tactics for Optimizing Crusher and Mill Efficiency: A Guide for Plant ...

2023.5.19 Did you know that 29% of plants spend 5 to 10% of their annual budget on maintenance, and 44% spend more than 40 hours a week performing maintenance? Considering this, crusher and mill efficiency must be one of the focal points of your business. Crusher and mill efficiency measures the ability to crush, grind, and convert raw material

Read More

Seven Critical Maintenance Items For Mobile Crushing Plants ...

2023.10.26 The seven critical maintenance items discussed in this article, including lubrication systems, conveyor belts, crusher components, screening components, electrical systems, dust control and suppression, and emergency systems, are essential for keeping mobile crushing plants operational, efficient, and safe. Routine maintenance not only

Read More

Mobile Crusher Plant - High Mobility To Save Transportation

At the same time, Aimix also provides iron separators and side belt conveyors for you to choose from, which you can choose according to your needs. The production capacity of the mobile jaw crusher plant can reach 45-400t/h. APY2-110J mobile jaw crusher plant. APY2-69J mobile jaw crusher plant Capacity: 60-160 (t/h)

Read More

Maximizing Efficiency with Portable Crusher Plant: A

2024.1.29 By choosing the right portable crusher plant, implementing effective maintenance practices, and prioritizing safety, businesses can enhance their crushing operations and drive profitability. Investing in portable crusher plants not only offers cost savings and environmental benefits but also improves the overall efficiency and flexibility

Read More

Dust Suppression System for Crusher Plants - EKA Mining

DUST SUPPRESSION SYSTEM FOR MINES CRUSHER PLANTS DUST SUPPRESSION SYSTEM FOR HOPPERS AND CONVEYORS At CMS, we give thorough site explicit Dust Control Management and Dust Suppression Systems for the stone crushers and industrial areas. We represent considerable authority in Mine Dust Suppression and take into

Read More

Preventive crusher and screen maintenance - Metso

Preventive maintenance technology explained with Metso Metrics. Metso Metrics technology for aggregates customers helps monitor, maintain and manage clients’ assets. Connected equipment is ensured by many

Read More

QH441-OperationManual - Crusher Works

2015.11.6 39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

Read More

The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

2023.2.23 Introduction. An aggregate crushing plant is a machine that processes a wide range of raw materials into high-quality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges. Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability

Read More

The Most Practical Jaw Crusher Repair and Maintenance Manual

2023.2.15 It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance. 1 Check whether the tooth peak to tooth valley is match with each other. 2 Regularly check whether the bolts and nuts have been tightened so you must ensure that ...

Read More

Crusher Plant Maintenance jobs - Indeed

Rock Plant Quarry Maintenance Mechanic. FST Sand Gravel. Corona, CA. $80,000 - $130,000 a year. Full-time. Day shift + 1. Easily apply. Repairing and maintaining rock crushing and screening plants in a quarry. Equipment includes crushers, screens, conveyors, and other associated equipment to.

Read More

Crushing and Screening Handbook - AusIMM

2021.6.24 Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading supplier of both unit machines and complete aggregates processing systems. Comprehensive process solutions Your system may involve a whole series of

Read More

Crusher maintenance tools - Metso

Our lifting tools make the maintenance of your crusher safer and more efficient. Our lifting tools are designed with OEM expertise, making them the best choice to lift Metso engineered and supplied crusher wear parts. We also offer lifting tools for certain Metso engineered Contender™ Series wear parts for Sandvik CH range crushers.

Read More

Stone Crusher Plant - Installation Guide - AIMIX GROUP

Regular maintenance of stone crusher plant to fix leaks and ensure proper functioning of water recycling systems is vital. The above are the whole procedures to ensure the efficiency of stone crusher plant working. Hope it is helpful to you. After you finish the stone crusher plant installation, please pay attention to the following tips.

Read More

A Balanced Approach to Crusher Maintenance - For

2005.9.20 Thompson believes two elements are crucial to achieving this kind of performance. "First, get a top-quality crushing plant designed for your specific needs. Second, establish a sensible ...

Read More

Mobile Crusher Plant in The Philippines - Wheeled

In fact, the choice of main jaw crusher model is also important. In the Philippines, many clients would like choose the feeding opening size, like 400×600mm, 500×750mm, 600×900mm, 900×1200mm, and

Read More

5 Types Of Stone Crushers Application and

Stone crusher is mainly used for crushing operation in quarry crushing plant and mining plant. There are 5 types of stone crushers: jaw crusher, impact crusher, hammer crusher, cone crusher, and VIS crusher. What is the

Read More

8 Tips for Crusher Safety Stewart-Amos

2022.10.27 Perform Regular Maintenance. Operate every crusher at an appropriate capacity to ensure rock crushing plant safety. Keep platforms and areas around the machine clean, and monitor the crusher’s

Read More

Mobile Crusher Plant - Factory Price - Aimix Group

Mobile crusher plant for sale is an efficient equipment used in the mining, construction, and recycling industries for crushing and screening granite, basalt, cobblestone, limestone, copper ore, raw ore material, construction waste, and other kinds of raw materials.. It consists of several accessories, including primary crushers, secondary crushers,

Read More

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap

Read More

Crusher Maintenance - An Absolute Solution to Crushing Plant ...

Following are five steps to help achieve the goal. 1. Know and follow the Rock Crusher Constraints. Every machine has a few reservations and this applies to a rock crusher as well. There are basically three limitations that are particularly important to be kept in mind while operating a crusher i.e. the horsepower, volume, and the crushing force.

Read More

Maintenance of Aggregate Crushers Agg-Net

2017.9.8 The most important aspect is to have a maintenance plan in place and execute it. Following a maintenance plan and carrying out daily inspections can yield increased service life. The plan should adhere to the recommendations of the manufacturer. Maintenance plans may differ slightly depending upon the machine, but most follow an

Read More

The basics of crusher maintenance - Rock Road Recycle

2019.2.11 Processing abrasive material, tight settings and uncrushables can accelerate wear. • Make adjustments to the aprons in small increments. This will allow you to achieve your desired results faster. • Lubricate the crusher bearings daily per the OEM recommendations. New grease will keep dirt out of the bearings, extending the life of the

Read More

Common Faults and Maintenance Guides of Stone Crusher Plant

Advantages of jaw crusher: The powerful crushing force of the jaw crusher is due to the pressure between its movable jaw and stationary jaw. This pressure is enough to crush hard rock into the desired particle size. The jaw plate of the jaw crusher has a large swing angle, which is also called large-scale jaw movement.This design allows the jaw plate to better

Read More

Rock Crushers, Stone Crushers, Screening and Crushing

200 kW. Capacity (by hour) 330 - 960 mtph (364 - 1,058 stph) Feed opening. 1,300 x 1,130 mm (51 x 45 in.) mm. Motor power. 160 kW (250 hp) Sandvik crushing and screening equipment. Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applications.

Read More