de broyage de ciment en Inde ultrafine POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- la separation par gravite

- convoyeur a chassis en acier

- machine pour fabrication de la maionese en France

- broyeurs à boulets pour capacité de 6 tonnes hr de manutention

- machine mobile séparateur magnétique concasseur

- composé combinaison concasseur concasseur

- broyeur mobile pour minerai de bauxite

- afrique gold minière concasseur sud

- sewa mobile concasseur di indonésie

- universal construction machinery

- pour concasseur à cone

- ceramico vidriado molinos de bolas

- concasseur comment calculer le cot de revient

- concasseur de pierre direction

- cone mobile techniques crusher

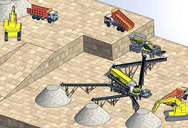

concassage et criblage de carriere

A review of modeling and control strategies for cone crushers

2021.8.15 We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. • The steady-state model of Whiten (1972) is still used today in recent works. • DEM models are limited to the mechanistic understanding of cone crushers. • Most control applications consist of PID and expert system rather than MPC. •

Read More

QH331 HYDROCONE PIONEERING SOLUTIONS FOR YOU

2019.4.10 The QH331 mobile cone crusher has been designed to meet the most exacting aggregate product quality demands through the use of the Sandvik CH430 cone crusher on a tracked chassis. Through this cone the QH331 is able to take advantage of the Sandvik developed CSC (cubical shape crushing) techniques, producing material of

Read More

Advanced comminution modelling: Part 1 – Crushers☆

2020.12.1 1. Twin roll crusher. 2. Cone crusher. 3. Vertical Shaft Impactor (VSI) These show the nature and level of fidelity that is now possible to include in particle scale crusher models including breakage of non-spherical particles and prediction of the product size distribution and throughput. Previous. Next. Comminution. DEM. Breakage. Crusher.

Read More

MOBILE CONE CRUSHER

2022.2.3 MOBILE CONE CRUSHER. TECHNICAL SPECIFICATION. The UH440i is a high quality, tracked mobile cone crusher that is robust and built to last. This heavy duty workhorse has proved itself worldwide in the toughest of

Read More

QS332 Cone crusher - SRP

Sandvik QS332 is a compact, robust mobile secondary cone crushing solution designed for versatility and ease of operation. Fitted with Sandvik CS430 "S" type gyratory cone crusher, it is capable of accepting large feed sizes whilst achieving high production capacities.

Read More

New developments in cone crusher performance optimization

2009.6.1 Abstract. This paper shall review Metso Minerals’ current 3D Discrete Element Method (DEM) modeling techniques, developed to allow a detailed study of the interactions of crushing design variables with actual rock mechanics.

Read More

Investigating the Variations in Crushers’ Daily Production

2021.8.3 Similarly, cone crushers apply compression to break the aggregate particles between the cone and the concave in such a way that the cone rotates in an eccentric motion inside the concave. Owing to the crushing chamber shape and the rock feeding style, cone crushers tend to generate more particles of cubical shape.

Read More

Mobile Cone Crushers - Lippmann Global

Mobile Cone Crushers - Lippmann Global. Select a Model. 300c 300c-r. 400c. LIPPMANN. 300c 300c-r. The Lippmann 300c and 300c-r are heavy duty cone crushers with an innovative material flow that maximizes

Read More

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Stone crusher. Jaw crusher. Cone crusher. Impact crusher. Aggregate production. 1 Introduction. Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [ 1 ]. In infrastructure industry, these equipment are available in different capacities ranging from 0.1 ton/hr. to 50 ton/hr.

Read More

A Guide to Mobile Crushing Plants: Types, Components

2023.2.24 Crusher: The crusher is the main component of the mobile crushing plant. It crushes the material into smaller pieces, reducing them to a size that can be transported by conveyors or other means. Conveyor: The conveyor is used to transport the crushed material to a designated area for further processing or stockpiling.

Read More

A Comprehensive Guide to Cone Crusher Types

2023.2.15 The mobile cone crusher is designed to be easily transported between sites and is usually mounted on tracks, which provides flexibility in terms of the types of terrain that it can operate on.

Read More

QS332 Cone crusher - SRP

400 mm (16 in.) Capacity. 344 mtph (379 stph) Sandvik QS332 is a compact, robust mobile secondary cone crushing solution designed for versatility and ease of operation. Fitted with Sandvik CS430 "S" type gyratory cone crusher, it is capable of accepting large feed sizes whilst achieving high production capacities.

Read More

Our Range of Trio® Cone Crushers Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

Read More

QH441 Cone crusher - SRP

Former Names: Extec X44, QH440 Mobile cone crusher. Additional product information QH441. Sandvik QH441 is one of the most flexible and heavy duty cone crushers on the market today. Specifically aimed at large scale aggregates producers, Sandvik QH441 has been designed utilizing the latest technology to ensure uninterrupted productivity and ...

Read More

Mobile Cone Crushers - Lippmann Global

400c. LIPPMANN. 300c 300c-r. The Lippmann 300c and 300c-r are heavy duty cone crushers with an innovative material flow that maximizes capacity and throughput while delivering a consistently high quality product. 300c Case Study – K.J. Services. FEATURES. SPECIFICATIONS. Mobile Cone Crushers Select a Model LIPPMANN 300c 300c-r.

Read More

Cone Crusher - Tips of Operation and Regular Maintenance

2022.3.22 Check whether the oil pump, cooler and filter work well. The scavenge oil must be lower than 60℃. Check the drain of the water seal. If there is no water in the water seal, the crusher must stop running. Pay attention to the sound of engine and gear, and check whether the working current of the motor is normal.

Read More

Leading Mobile Crusher And Screen Manufacturer

5 天之前 We are a large intelligent equipment manufacturer. We are professional and reliable experts in the field of mobile crushers (crushing, screening, washing, feeding, transportation, centralized cyclone, and other equipment). Read More». Established In 2018, But Over 30 Years of Experience. 300+ Company Staff.

Read More

Sandvik Cone Crushers - SRP

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize

Read More

Nordberg HP Series cone crushers – High performance

2023.1.20 19. Nordberg HP Series cone crushers 3. Proven and predictable production. HP Series cone crushers provide predictable and consistent capacity, end product size, gradation and shape, making them a safe choice for aggregates and mining processes. The crusher setting is mechanically fixed while crushing and it is secured by

Read More

Unveiling the Advantages and Applications of

2023.2.28 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry. Their unique design and superior performance make them a popular choice for a wide range of

Read More

A Detailed Overview of Cone Crushers and What

2020.6.3 Most cone crushers have a feed opening size of 5-14", so material that's larger than the maximum size allowable will need a first stage of crushing before they can be fed into a cone crusher. Final Product

Read More

Understanding the Cone Crusher Working Principle: How It

2023.2.23 The cone crusher’s unique design allows it to rotate at high speeds and crushes material through a combination of compression and impact. When the cone crusher is in operation, the spindle rotates around its own axis, causing the mantle to move back and forth. The mantle is the cone-shaped part of the crusher that moves in a circular motion ...

Read More

Nordberg HP Series cone crushers High performance

2023.1.20 Série Nordberg® HPTM pour les granulats. Lorsque vous avez besoin d’un concasseur pour produire des granulats, le concasseur à cône Série Nordberg HP est le choix idéal. La série HP est reconnue pour ces excellentes performances en termes de capacité de débit, de réduction et de qualité du produit fini.

Read More

MCO 110i PRO Mobile cone crushers Kleemann - Wirtgen

The MOBICONE MCO 110i PRO mobile cone crusher stands out thanks to its extremely robust design and impressive performance. As an option, the plant can be operated via an external power source and impresses with its low-maintenance operation. Extremely robust design. Very high production outputs with low-maintenance operation.

Read More

Crawler Mobile Cone Crusher - MECRU Heavy Industry

2023.5.17 Product Introduction. Crawler mobile cone crushing plant, with cone crusher as the host equipment for crushing Equipped with track driving chassis to convert the mobile site. Including crawler single-cylinder hydraulic cone crusher and crawler multi-cylinder hydraulic cone crusher. Crawler mobile rack can be installed according to

Read More

CRUSHER DEPARTMENT : KOTOBUKI ENGINEERING

2013.11.29 The Crusher Department is concerned with equipment for production of suitable crushed rock (aggregate) by size reduction of quarried rock. Rock quarries are the normal home of rock crushers. Material up to about 800mm blasted from the ground is reduced in size to the correct specification for final use. Aggregates for concrete are

Read More

Lokotrack® LT220GP™ mobile cone crusher - Metso

Features. Lokotrack® LT220GP™ mobile cone crusher plant is designed for secondary and tertiary hard rock crushing. It is available with a belt feeder or a 2-deck pre-screen that together with a the Nordberg® GP220 crusher offers up to 50% more capacity for aggregates contracting. Contact our sales experts.

Read More

MCO 110 PRO Mobile cone crushers Kleemann - Wirtgen

The MOBICONE MCO 110 PRO mobile cone crusher stands out thanks to its extremely robust design and impressive performance. As an option, the plant can be operated using an external power source and it requires impressively little maintenance. Extremely robust design. Very high production output with low-maintenance operation.

Read More

Nordberg® HP300™ cone crusher - Metso

Nordberg® HP300™ cone crusher is a versatile rock crushing machine frequently utilized as a secondary, tertiary, or quaternary crusher in aggregates production or in mining operations. It is part of the world’s most popular cone crusher series, and designed for high productivity, with low operating and wear costs. Contact our sales experts.

Read More

Mobile cone crushers for recrushing Kleemann - Wirtgen

The mobile MOBICONE cone crushers are used in medium-hard to hard and abrasive natural stone as well as for raw material preparation in mining applications. The cone crushers delivery top quality cubic final grain sizes in the 2nd and 3rd crushing stage. The MOBICONE plants are available in different sizes and for various applications.

Read More

Cone Crusher Troubleshooting Guide: Common

2023.2.24 Cone crushers are a vital part of many industries, including mining, construction, and recycling. They are used to crush and grind materials to a specific size, making them suitable for further processing.

Read More

MOBILE CONE CRUSHER - SRP

2023.9.13 The UH440i is a high quality, tracked mobile cone crusher that is robust and built to last. This heavy duty workhorse has proved itself worldwide in the toughest of applications and in all climatic conditions. Featuring the CH440 crusher and an automated onboard “intelligence” system, this results in optimal

Read More

Mobile cone crushers for recrushing Kleemann - Wirtgen

The cone crushers deliver excellent cubic final grains in the secondary and tertiary crushing stages. The MOBICONE plants are available in different sizes and versions and for different applications. The cone crusher is suitable mainly in the linking with primary crushers and screening plants. Feed capacity up to approx.: 298 US t/hr. 518 US t/hr.

Read More

Cone crusher basics in 4 minutes - rockprocessing.sandvik

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing ...

Read More

Ultimate Guide to Cone Crusher Liners: Materials, Designs

2023.2.21 Types of Materials for Cone Crusher Liners. One of the key factors to consider when selecting cone crusher liners is the type of material used. Two main types of materials are commonly used for liners: steel and composite materials. Steel liners are often made of manganese steel, a type of high-strength steel that is known for its toughness

Read More

Delta Group Purchases World’s Biggest Mobile Cone-Crusher

2010.10.20 The TC1885 is powered by a 27 litre 875 HP, twin turbo, V12 Caterpillar engine. It contains over 5 tonnes of liquid when fully fuelled and all hydraulic systems charged. The crushing unit of the ...

Read More

Cone Crushers Mobile High Productivity Terex Finlay

2024.5.10 The Finlay® C-1554 tracked cone crusher is the ultimate mobile solution for any aggregates producer or contractor looking for a high productivity machine that provides large reduction ratios and an excellent cubical shaped end product. The robust design of the plant enables it to accept an all in feed and makes it particularly suitable

Read More

A Comprehensive Guide to Cone Crusher Prices: Factors

2023.2.24 In conclusion, purchasing a cone crusher requires careful consideration of various factors. The price of a cone crusher can be affected by brand, model, size, features, and market demand, among other factors. Comparing prices and specifications of different models from various manufacturers is crucial to finding the best value for your specific ...

Read More

HP Series Cone Crushers - International Crusher Solutions

2015.10.12 By operating the HP cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher percentage of on-spec product. The HP cone crusher creates a higher value product with less waste. Mobile : The NW300HP is a highly mobile, closed-circuit crushing and screening plant.

Read More