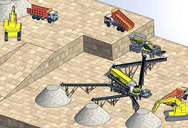

sans obstruer concasseur concasseur POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- oberg p concasseurs afrique du sud

- broyeur à cône dolomite occasion nigeria

- pieces haut de gamme de concasseurs

- trituradoras mineras de oro móvil

- materiel dexploitation miniere pour les prix de lor au ghana

- dezine de trituradora de piedra

- machine occasion pour cuivre

- broyeur centrifuge pour le rock

- Concasseur Di Chandikhol Concasseur à machoires sortie

- irfan concasseur à sable rondelle usine

- drotsky broyeurs harare

- la drage fixe processus de charbon

- dans les fabricants de dinde

- fournisseur de granulats et de sable à Guwahati

- calculation of coal crusher

concassage et criblage de carriere

Energy Evolution and Coal Crushing Mechanisms Involved in

2023.12.16 The outburst process is complex and involves multiple variables. The gas expansion energy in an outburst can be calculated using engineering thermodynamics theory (Yu et al., 2013; Wang et al., 2023 ), thus: $$W= {\int }_ {1}^ {2}Pdv=\frac {1} {n-1}\left ( {P}_ {1} {V}_ {1}- {P}_ {2} {V}_ {2}\right)$$.

Read More

Drive power calculation of a crushing machine working

The power of the electric motor is determined taking into account the power expended to overcome all resistance forces during the operation of the crusher: NDR = N. 1 + N 2 , (1) . where N1 – the power required for crushing the material; N2 – power expended on friction in the bearings; η – transmission efficiency.

Read More

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

height of the crusher’s working chamber h = 250 mm, the outlet slot er = 20÷30 mm, the angular velocity of the drive shaft (no-load running) n = 388 rpm, moving jaw displacement s ≈ 6 mm, gear ratio of V belt 3.2, rated engine power (type SZJe 34b) Nzn = 4 kW. The material used in the tests (feed) was a lime-

Read More

Modeling of coal breakage in a double-roll crusher

2012.12.1 Using the equations above, it is possible to calculate the mass balance including the size reduction and growth by the breakage and agglomeration of particles and thus to predict the particle size distribution of a product from a double-roll crusher. 4.4. Determination of model parameters.

Read More

Calculation model of coal comminution energy consumption

2016.6.1 Therefore, in coal preparation process, the adjustment of the crusher should be performed considering coal grindability or crushability and the feed coal size distribution. At last, an empirical model of comminution energy was proposed and validated by the measured values with ±25% of accuracy.

Read More

Energy Efficiency Optimization of Coal Conveying Systems

2017.5.1 Coal conveying systems mainly includes belt conveyors and crushers. On the basis of conveyor and crusher energy models, this paper presents an energy efficiency optimization strategy for coal conveying systems by taking feed rate, belt speed and rotational speed of crusher as optimization variables.

Read More

Capacity Calculations of the Crasher with Stops on a Roll

2022.8.21 The share of produced energy spent on crushing is more than 5% in the global energy balance. In this paper, we consider the schematics of a crushing machine with stops on the roll, the design of which forms a complex stress state in the crushed piece under the simultaneous action of normal and shear stresses.

Read More

Energy Evolution and Coal Crushing Mechanisms

2024.1.27 Original Paper. Energy Evolution and Coal Crushing Mechanisms Involved in Coal and Gas Outburst. Chaolin Zhang,1,2 Peizhong Wang,1Xianfeng Liu,3,4Enyuan Wang,1,2Qiaozhen Jiang,1and Mingliang Liu1. Received 5 July 2023; accepted 14 November 2023 Published online: 16 December 2023.

Read More

Modeling and Improving the Efficiency of Crushing Equipment

2023.6.30 Crusher modeling is hardly achievable without identifying the basic parameters of crushers; this is an essential basis for any model [ 6 ]. The book «Mineral Processing Design and Operations ...

Read More

How to calculate the productivity of a coal crusher? - LinkedIn

2023.6.7 For example, if the crusher can process 10 tons of coal in one hour and it has been worked for 8 hours, then the productivity rate is 10/8 = 1.25 tons of coal per hour. coal crushers

Read More

Study of the Energy-Power Parameters of the Crushing

2023.3.6 Abstract Analytical method for determining the energy-power parameters of the crushing process in a rotary hammer crusher with a grate is proposed. Using the method of equivalent power required for the electric motor drive of the crushing machine at the steady mode of operation and basic laws of general mechanics, we explain the following:

Read More

Analisis Efektivitas Coal Crusher Dengan Metode Overall ...

Based on the calculation of the OEE average value of coal crusher machines in August 2018 to March 2019 amounting to 55.5% with a availability rate of 78%, a performance rate of 77%, and a quality rate of 99.9% which is still far from world standards namely Avaibility> 90% performance rate> 95%

Read More

Experimental study of coal liberation: Electrical disintegration

2009.7.1 The roll crusher tests were carried out under various conditions and roll crusher product with a similar size distribution as the ED product was investigated further. Coal feed weight was 100 g, the same as in the ED test. ... Mineral content of feed coal calculated by the norm calculation method. 4. Results and discussion4.1.

Read More

en/170/capacity calculation of vertical crusher.md at main

Find and fix vulnerabilities Codespaces

Read More

(PDF) The Influence of the Structure of Double Toothed Roller Crusher ...

2018.11.7 By taking the double toothed roller crusher as case study, the optimization results show that proposed method can significantly improve the calculation efficiency, and compared with the ...

Read More

(PDF) Vibration Test and Shock Absorption of Coal Crusher Chambers

2020.9.15 When static design method is adopted to calculate the bearing capacity of the supporting structure subjected to the dynamic load of the coal crusher, the dynamic coefficient of a coal crusher is ...

Read More

Research on Structural Design of Coal Crusher House in

2023.10.14 In the coal crusher house, floor beams directly support-ing the coal crusher are not subject to vertical vibration calculation when their high-span ratio meets the require-ments of Table 1[1 ...

Read More

how to calculate the production capacity of cone crusher

2023.1.28 The bulk density of the material being crushed. Once you have this information, you can use the following formula to calculate the production capacity of the crusher: Capacity = (60 x Speed x ...

Read More

Minerals Free Full-Text Torque Analysis of a

2021.8.13 Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant

Read More

Fragmentation energy calculation model of coal crushed

2024.3.31 Impact crushing tests. The impact crushing test of coal was conducted in laboratory to get the crushed coal particles. The impact load was achieved by a drop weight system as shown in Figure 2. The drop weight with 73.35 kg was released from a height of 2.5 m, which can accelerate the drop weight maximum to 7 m/s.

Read More

sbm/sbm cost calculation of coal crusher.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Read More

Capacity Calculations of the Crasher with Stops on a Roll

2022.8.21 The design has been developed for a single-roll crusher with the forced supply of destroyed material into the crushing zone [].The capture of a crushed piece occurs due to the stop located on the roll (see Fig. 1); in this case, the condition for formation of a complex stress state in the crushed piece is observed, and the energy consumption is

Read More

GitHub

sbm how to calculate capacity of coal bunkercoal silo design calculation xls BINQ Mining coal silo design calculation xls.Posted at:November 19,2012[.Bulk Handling Global Online S

Read More

Experimental study of coal liberation: Electrical disintegration versus ...

2009.7.1 Section snippets Samples. Clean coal sample of Nantun (China) coal was used for the experiments. Massive coal samples were crushed by mechanical crusher and sieved to obtain the 4.0 to 8.0 mm size fraction (a 1:1 mixture of 4.0–5.6 and 5.6–8.0 mm) and the fractions with specific gravities (S.G.) of 1.35 to 1.45 were selected by a sink-and

Read More

Spring Support of Coal Crusher Foundations in Power

2024.1.11 Spring Support of Coal Crusher Foundations in Power Plants. Such an approach usually produces a de-sign with a concrete slab on tall columns, all supported on a heavy base mat. This design attempts to resist the dynamic ef-fects and minimizes the dangers of soil settlement. Nevertheless, risks remain as this con-ventional design is

Read More

Calculation model of coal comminution energy consumption

2016.6.1 In this paper, experiments on coal comminution energy under conditions for CFB boilers were carried out. The R–R distribution was used to describe the size distribution of the crushing product with high COD. An empirical model of comminution energy was proposed. The model provides good accuracy by correlating the experimental data within

Read More

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

height of the crusher’s working chamber h = 250 mm, the outlet slot er = 20÷30 mm, the angular velocity of the drive shaft (no-load running) n = 388 rpm, moving jaw displacement s ≈ 6 mm, gear ratio of V belt 3.2, rated engine power (type SZJe 34b) Nzn = 4 kW. The material used in the tests (feed) was a lime-

Read More

Dynamics in double roll crushers - ScienceDirect

2017.4.1 Tests were conducted with the drive uncoupled from the crusher just before the crushing event to measure the slight deceleration during crushing. This allows the calculation of the energy consumption for comminution. 50 samples of limestone (Bad Kösen, as per Table 2) were tested at a nominal speed of 124 RPM and s = 2.0 mm gap

Read More

Calculating Motor Hp Requirement For Coal Crushers

coal crusher power calculation. Power to be transmitted = 450 Hp ... InfoMine . Coal plants will use roll crushers, either single roll or ... How the the rock crusher motor power is ... jaw crusher 400x225mm with 25 hp motor price 10 x 21 used ...

Read More

en/112/coal crusher business plancoal crusher calculation

Contribute to dinglei2022/en development by creating an account on GitHub.

Read More

Modeling of coal breakage in a double-roll crusher

2012.12.1 To represent the particle behaviors and to predict the product size distributions of coal breakage products by a double-roll crusher, a new combined breakage–agglomeration model has been ...

Read More

Construction Working and Maintenance of ... - Practical

2018.12.26 Construction Working and Maintenance of ... - Practical Maintenance

Read More

Crushing of coal and calculation of size reduction efficiency.

2015.2.25 Crushing of coal and calculation of size reduction efficiency. - Download as a PDF or view online for free ... Eli Blake patented the Double toggle Blake Jaw Crusher in 1858. The Blake type Jaw crusher has fixed feed opening where as the dodge type jaw crusher has fixed discharge opening. 2/25/2015 6:58:05 AM 5 6.

Read More

Standard operating procedure of CHP Dust extraction

6 天之前 Ensure coal bunker is 90%. Stop coal feeding. Keep OFF water sprinkler system. Ensure coal belt conveyors are empty there is no any coal on belts, vibro screen crusher. Stop CHP as per sequence wait for 10 minutes then stop dust extraction system. Have field round ensure no any coal saturation no any abnormal observations.

Read More

en/164/calculate coal crusher capacity.md at main

Find and fix vulnerabilities Codespaces. Instant dev environments

Read More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017.6.30 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

Read More

Estimate Jaw Crusher Capacity - 911 Metallurgist

2016.2.17 Estimate Jaw Crusher Capacity. Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): = 2800 x 0.25 x 0.5 x 0.5 x 225 x (1-0.2)/60 = 525 kg/hr = 13 TPD vs 300 to 420 TPD —> I can’t make this work! My friend Alex the SAG Mill Expert, says this equation you picked up doesn’t look right.

Read More

en/167/calculate for the capacity of a double roll crusher.md ...

Host and manage packages

Read More