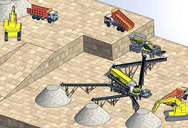

la maquina chancadoras de asfalto POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- concasseurs de gravier mobiles à louer alberta

- proposition de pret de la banque pour une usine de broyeur de pierres

- utilisation de sable de silice

- concasseur à mâchoires prochange profil de

- pdf concasseur de mchoires pe 100 120

- trituradora de piedra de mini antiguedades en venta nafta

- moulin à boulets à grille à compartiment

- coût concasseur angola concasseurs

- verdadera imagen de la trituradora de mandibula

- le minerai de fer alunite dans les carrieres de calcaire

- fabrication de sable inde prix de la machine de ciment de lusine

- Broyeur A Boulets Principaux Paramètres Techniques

- broyeur de pierres sur le loyer à yamunanagar

- broyeur de cuivre de capacité

- pulverizer raw coal size

concassage et criblage de carriere

Bowl Mill Coal Pulverizer

3 天之前 Working of Coal Pulverizer. The maximum capacity of a pulverizer is dependent on the following: 1. Pulverizer size 2. Raw coal properties – Hardgrove index and moisture level 3. Pulverized coal fineness. The raw coal is fed into a

Read More

Study on coal pulverization characteristics and gas

The coal's particle size distribution properties after pulverization and the gas desorption behavior driven by pulverization are of profound meaning to the study of coal and gas outburst mechanism. In this paper, based on the impact crushing experiment, the tectonic coal and primary coal are crushed under different impact energy conditions.

Read More

Industrial Coal Pulverizer Model Simulation and Parametric ...

2018.1.1 The energy efficiency of a typical thermal power plant is about 35-40%. Thermal power plants have pulverized coal-fired boilers. The pulverizer is one of the most important unit of the plant. The coal after being crushed in the pulverizer to a specific mesh size is then taken to the boiler for combustion.

Read More

Optimum Operation and Maintenance of EL Pulverizers

2018.6.3 Raw Coal Size. Maintaining optimum sizing of raw coal to the pulverizer is mandatory in achieving capacity and fineness. Optimum raw coal feed size for EL pulverizers is ¾” to 1”. Raw coal feed should never exceed 1¼”, raw coal this size can plug throats and cause vibration. Raw coal that is too fine can plug

Read More

A Comparison of Three Types of Coal Pulverizers

2024.2.19 tion, particularly when pulverizing high moisture and/or oversize coal. A TRITA Pulverizer The ATRITA pulverizer is a high-speed, compactly designed machine which reduces raw coal to pulverized coal by the combination of crushing, impact and attrition. The AT RITA has separate crusher, pulverizer,

Read More

Coal Pulverizer

4 天之前 Raw coal enters the top of the pulverizer through the raw coal feed pipe. The raw coal is then pulverized between the roll and rotating ring. Hot air is forced in through the bottom of the pulverizing chamber to remove unwanted moisture and transport the coal dust up through the top of the pulverizer and out the exhaust pipe directly to the burner.

Read More

CFD based investigations into optimization of coal pulveriser ...

2009.9.1 Coal pulverizers or mills grind coal typically from 10–50 mm size coal lumps to provide fine coal dust particles usually less than a micron up to several microns in size (with at least 70% by weight not exceeding 75 µm).

Read More

Pulverizers 101: Part 3

2020.8.28 Raw coal with a preferred maximum size of about 3⁄4” enters the mill. Let’s use bituminous coal with 10% total moisture as an example. The coal is dry to the touch and the 10% moisture is inherent moisture - moisture that will not be removed by air-drying or by being stored on a sunny summer day on the coal pile.

Read More

The right Pulverizer for reliable size reduction of any material

The RETSCH pulverizer range covers applications from the preliminary size reduction of particles of several centimeters to fine grinding down to the nano range. Retsch Pulverizer Mill. A good pulverizer guarantees reproducible sample preparation, which is the basis for any reliable and accurate laboratory analysis.

Read More

Pulverizer Capacity is not simply “tons throughput per

2016.5.3 Pulverizer capacity is comprised of five major factors. These are throughput, fineness, Hardgrove grindability, moisture content and raw coal size. Therefore, throughput is only one component of pulverizer capacity. All five factors play a part. For example, when the fineness is reduced, the throughput can be increased without the pulverizer ...

Read More

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Raw coal (sometimes pre-treated) is fed into the centre of the grinding table. The grinding table rotates which causes the coal to move towards the outer periphery of the grinding table. The coal is ground between the rollers and grinding table. When enough coal has been reduced in size, it will flow over the top of the dam ring (retention ring).

Read More

alstom coal pulverizers - stone-pulverizer

2019.3.26 Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size, moisture content, and ... Check now. Olympic Wear - Abrasion Resistant Castings and

Read More

Industrial Coal Pulverizer Model Simulation and Parametric ...

2018.1.1 The coal-pulverizer is an important unit, which pre-processes coal-fuel fed to the boiler in coal-based thermal power plants. It is extremely important to comprehend the operational behavior of the coal pulverizer unit for good performance of the boiler and overall coal power-plant. This paper describes the first principle based energy and mass ...

Read More

Pulverizers for Laboratory - Gilson Co. - GlobalGilson

Operates on 220V or 440V, 50/60Hz, three-phase power supplies. Vibrating Cup Pulverizer uses an 8in (203mm) diameter bowl with grinding ring and puck reduce wet or dry 0.5in (12.7mm) rock, ore, minerals, and soil to analytical size. The Pulverizer has a 250ml sample capacity, a 1hp motor, 0-100 minute digital timer, and an emergency stop button.

Read More

Pulverizers 101: Part II - POWER Magazine

2011.10.1 Pulverizer “capacity” is the amount of coal a pulverizer can grind at a given raw feed rate, to a given fineness, at a certain Hardgrove Grindabilty Index (HGI), and at a specific raw fuel ...

Read More

Coal Pulverizer

4 天之前 Raw coal enters the top of the pulverizer through the raw coal feed pipe. The raw coal is then pulverized between the roll and rotating ring. Hot air is forced in through the bottom of the pulverizing chamber to remove unwanted moisture and transport the coal dust up through the top of the pulverizer and out the exhaust pipe directly to the burner.

Read More

Coal Pulverizer – Power Plant Pall Corporation

6 天之前 In order to protect the coal pulverizer lube system components, Pall recommends maintaining a fluid cleanliness level of ISO 16/13 or better. This can be accomplished through the use of Athalon AS grade (ß12 (c)≥

Read More

Experimental investigation of breakage and energy

2017.2.15 Breakage of raw coal in vertical spindle pulverizer (VSP) is extremely essential to yield the pulverized fuel (PF), which should be fine enough for the effective combustion in boilers. In 2010, nearly 40% of world electricity was generated by coal-fired plants [1]. ... The energy-size reduction of coal relates to both organic and inorganic ...

Read More

Coal Crushers Coal Pulverizers Mills Williams Crusher

Contact us today to discuss your application in detail with one of our experienced sales engineers. Call (314) 433-5464, email us at info@williamscrusher, or locate an agent near you. Williams Patent Crusher has become the industry leader in coal-crushing and pulverizing equipment. Learn more about our products.

Read More

Pulverizer Plant OM Aspects

2013.12.6 Pulverizer Plant OM Aspects Dr. T K Ray NTPC Limited E-mail: rayt3@asme ... Maximum Mill capacity vs PF fineness at 12 % Raw coal moisture and at Coal HGI 100-110 33.00 34.00 35.00 36.00 37.00 38.00 39.00 40.00 41.00 ... • Size of raw coal • Mill wear (YGP) • Maintenance practices 44

Read More

ISSN (Print) : 0973-0338 Central Power Research Institute

the coal. Smaller size coal chokes the coal bunkers and feeder pipes which aggravates the increase in moisture content. Storing, transportation, dust hazards, and fire also need to be considered when choosing the size of coal. An optimum size of 25 to 50 mm of coal is preferred for the efficient performance of the pulverizer. 1.2 Coal ...

Read More

Pulverised Coal - an overview ScienceDirect Topics

The raw coal is then fed into the pulverizer along with air heated to about 330°C (650°F) from the boiler. As the coal gets crushed by the rolling action, the hot air dries it and blows the usable fine coal powder out to be used as fuel. The powdered coal from the pulverizer is directly blown to a burner in the boiler.

Read More

Guide To Powder Pulverizers - TodayMachine

Step 1: Define Your Requirements. The first step in sourcing a powder pulverizer is to define your requirements. This will help you determine the type of machine you need, including the power, capacity, and size. Consider the type of materials you need to pulverize, the desired particle size range, and your required throughput.

Read More

Coal Pulverizer - Pall Corporation

4 天之前 Raw coal enters the top of the pulverizer through the raw coal feed pipe. The raw coal is then pulverized between the roll and rotating ring. Hot air is forced in through the bottom of the pulverizing chamber to remove unwanted moisture and transport the coal dust up through the top of the pulverizer and out the exhaust pipe directly to the burner.

Read More

CFD based investigations into optimization of coal pulveriser ...

2009.9.1 A dimensional sketch of a typical pulverizer is presented in Fig. 1 (a).A schematic diagram showing the air and particle streams in a pulverizer are presented in Fig. 1 (b). The raw coal from the coal feed chute (8) mixes with returned oversize material (7) to form a mixed stream that passes between the grinding balls and bottom grinding ring in

Read More

Comparison of energy efficiency between E and MPS type

2017.7.1 0.5%–2% gross power generation of coal power plant is consumed by vertical spindle pulverizer (VSP), and it is essential to select a VSP with better operational performance. Simulated studies of lab-scale mills, which show the similar breakage mechanism with VSP, and industrial sampling on VSPs are conducted to compare

Read More

Coal mill pulverizer in thermal power plants PPT - SlideShare

2012.11.17 20. 13.1.Fineness Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance. The mill

Read More

Dynamic Modelling and Simulation of Coal Pulverizer

2021.9.4 dynamic modelling of coal pulverizer [11, 12, 14, 15]. The model parameters are defined in Table 1. The mass of coal to be pulverized depends on the mass flow of the raw coal, wc, the return flow of the particles rejected by the classifier, wret, and the grinding rate which is proportional to the mass of raw coal on the grinding table, mc.

Read More

Development of a pilot roller test machine for investigating

2015.3.1 Associated minerals in the raw coal increase the energy consumption and abrasion of grinding media of vertical spindle pulverizer (VSP). Moreover, the low separating efficiency of classifier in VSP leads to the return of fines to grinding table, worsens the grinding phenomenon and make the energy-size reduction of coal complex.

Read More

Raw Coal Spillage Or “Pyriting”

Air velocity across the vane wheel annulus must be in the range of 7,000 Fpm to 7,500 Fpm to maintain suspension of raw coal of ¼” to 1” in size. In some cases spillage can be aggravated by or caused by other variables. ... Only Trace amounts of Coal should be discharged from the pulverizer. No raw coal should be discharged through the ...

Read More

How To Maintain a Coal Pulverizer? (All You Need To Know)

2024.4.10 The raw coal is delivered to the feeding device of the coal mill, and at the same time the hot air with a temperature of about 300°C also enters the feeding device through the air inlet pipe, where the raw coal containing moisture starts to exchange heat. ... When the raw coal enters the drying chamber of the coal pulverizer, a special lifting ...

Read More

Coal Pulverizer Price, Manufacturers Sellers in India

To order a Coal Pulverizer, one has to click on the product one is willing to buy. On the product page, a specific button is mentioned on the Coal Pulverizer detail page called “Request callback”. After clicking the button, a pop-up window with a form named “Ask the seller” will open. Just fill up your contact details, name, and order details about Coal

Read More

Atrita Coal Pulverizers - Babcock Power

2024.2.19 Integral fan purges the pulverizer of coal dust after the coal feed is stopped As raw coal and primary air enter the crusher section during start-up, air temperature is lowered as coal moisture is evaporated and only relatively cool air comes in contact with the pulverized coal Easy Access for Maintenance

Read More

Experimental study effect of classifier pulverizer opening

2019.12.10 Pulverizer is used to crush coal, so it is designed to supply the right size of coal for combustion in the boiler. to get the optimum performance and capacity of the pulverizer, the pulverizer must be used according to the design of the pulverizer taking into account the index Hardgrove Grindability Index (HGI), raw coal size and moisture content.

Read More